Nord Drivesystems Offers Drive Solutions at IPPE 2024

Nord’s smooth body gear units adhere to hygiene guidelines with their easy-to-clean surfaces.

Nord Drivesystems is once again attending the International Production and Processing Expo (IPPE) to showcase their solutions for the poultry and meat processing industry. Nord’s modular product system includes compact gear units, high-efficiency electric motors, and precise, intelligent electronic controls with a variety of surface protection options. This year’s expo is taking place January 30 – February 1, 2024, at the Georgia World Congress Center in Atlanta, GA.

Visit Nord at Booth BC-40087 to see these specialized solutions:

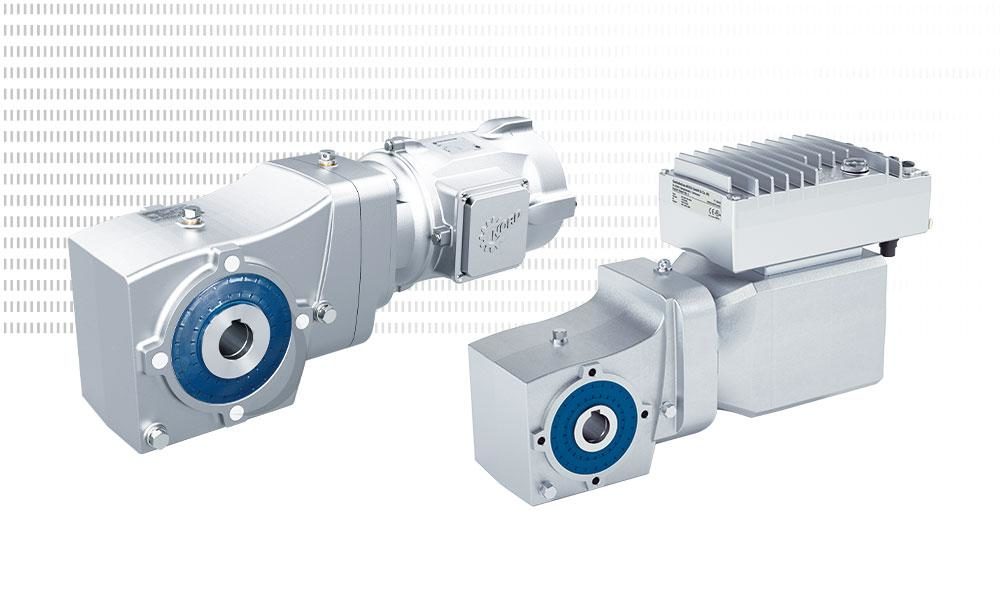

Smooth Surface Gear Units and Motors

Smooth surface gear units are made from a high-strength, aluminum alloy housing that provides an easy-to-clean surface with an optimized design that reduces the number of trapped particles. Available gear units include a range of Nordbloc.1 helical inline gear units, Nordbloc.1 helical bevel 93.1 series, and Universal SMI worm gear units. Additional protection options such as potted terminal boxes, Quadrilip seals, condensation drain holes, and moisture resistant varnished dipped windings are also available to keep moisture and unwanted debris from entering the gear unit. Smooth surface IE3 motors with a variety of protective coatings and finishes are also available in a HM series.

Overhead Conveyor Drives

Overhead conveyor drives feature heavy-duty construction and high-quality machined components to provide long lasting performance. The drives have two main features: a standard VL3 spread bearing design with a dry cavity that enables the drive to handle high overhung loads and an optimized oil leakage protection system with Quadrilip seals. With their output mounting flange and shaft, they allow for easy drop-in replacement for industry standard footprints. Thanks to their energy efficiency and minimal maintenance requirements, overhead conveyors have a low total cost of ownership, long service life, and deliver reliable operation.

Screw Conveyor Package

Nord’s Screw Conveyor Package is a compact, cost-effective alternative to traditional screw conveyor drives and is available for Unicase parallel shaft gear units and Unicase helical bevel gear units. Closely stepped speed ratios combined with a directly coupled motor or NEMA C-face input eliminate the need for top motor mounts, pulleys, belts, and guards, minimizing parts for easier maintenance, increased reliability, and superior drive performance. The package also features versatile mounting with multiple bolt patterns, a standard CEMA flange and shaft assembly, and a Quadrilip sealing system to protect the drive from contaminates.

IE5+ Synchronous Motors/DuoDrive Integrated Gear Unit and Motor

IE5+ permanent magnet synchronous motors are manufactured in-house at Nord and offer the highest efficiency currently available. The non-ventilated variant (N-design) offers a smooth surface for easy cleaning in hygienic environments and is fully compatible with their line of gear units and variable frequency drives. Thanks to their high efficiency and constant torque over a wide speed range, these motors can reduce the number of system variants, provide a lower total cost of ownership, and offer a fast return on investment.

DuoDrive combines the high efficiency of IE5+ motors with a single-stage helical gear unit in one smooth, compact housing. Plug-and-Play capabilities make for easy, fast commissioning and minimum downtime when units need maintenance or replacement. The units are also optionally available with IP69K ingress protection and deliver optimized system efficiency, quiet operation, and high-power density.

Nordac On/On+ Variable Frequency Drives

Nordac On/On+ variable frequency drives were developed for the specific requirements of horizontal conveyor technology. Nordac On VFDs are made for use with IE3 motors while Nordac On+ VFDs are optimized for combination with IE5+ synchronous motors. These VFDs are characterized by an integrated multi-protocol Ethernet interface, full pluggability, and a very compact, reliable design for IIoT environments.