The USDA is responsible for regulations and enforcement within food agriculture, meat processing, and poultry processing, including the manufacturing, handling, and packaging of food items. USDA requirements for materials are satisfied if those materials are FDA-compliant, but the agency may require a letter guaranteeing that products are being manufactured in accordance with regulations if they are used in direct food contact.

3-A Sanitary Standard Inc. (3-A SSI)

Comprising many representatives from government agencies, manufacturers, and processors, 3-A SSI is an independent, not-for-profit organization created to set standards and best practices for dairy equipment and processes. Many states require that dairy equipment meet 3-A standards and that the 3-A symbol be prominently displayed. For a material or piece of equipment to display the symbol, it must use 3-A-approved materials. The organization annually publishes a list of approved materials by product, grade, form, and supplier, and materials may not be replaced by generic alternatives.

NSF International (formerly the National Sanitation Foundation)

An independent organization, NSF sets the standards regarding all direct and indirect drinking water additives. To display the NSF symbol, a manufacturer needs to apply for approval. Such approval is for a finished product or device, not for specific materials or components. However, all components within the device must comply with the standards.

American Society for Testing and Materials (ASTM)

ASTM is an independent, not-for-profit organization created to establish standards for a range of products, systems, and materials. Compliance with the guidelines is strictly voluntary, and guidelines are not binding in a legal sense unless they are referenced by a governmental body in a regulation or are referenced in a specific contract.

European Organizations

The European Hygienic Engineering and Design Group (EHEDG) does not issue standards. However, it publishes guidelines for the cleaning and manufacturing of food processing equipment. Some European countries require that equipment be tested and approved by the EHEDG. The International Dairy Federation (IDF) and the International Standards Organization (ISO) also set cleanliness standards in Europe.

Best Washdown Design Materials

Materials selection is critical for the bearing, shaft or rail, and seal components in linear motion design for washdown environments because it is key for meeting corrosion-resistance and machine performance requirements, standards, and regulations.

Stainless steel is typically the preferred material for general use in direct food contact areas because of its corrosion resistance and durability. Variations in stainless steel grades typically involve different levels of chromium and nickel.

300 Series Stainless Steel

In general, 300 series stainless steel is the most widely accepted material for food and medical applications. It is relatively soft, cannot be hardened, and is also nonmagnetic. Each grade discussed below might have different types with slightly different formulations and varying strengths and weakness based on additions to the mixtures.

303—Called A1 under ISO standards, 303 is a free machining version of 304 due to added sulfur and phosphorus.

304—Called A2 under ISO standards or 18/8 due to the 18% chromium and 8% nickel in its makeup, 304 is the most common grade of stainless steel.

316—Called A4 under ISO standards or 18/10, 316 is the most commonly used alloy for food- and pharmaceutical-grade applications. The addition of up to 3% molybdenum aids in prevention of corrosion from industrial chemicals and solvents, particularly pitting that can be caused by chlorides.

400 Series Stainless Steel

There are several types of 400 series materials. The most widely available and most used in industry is 440. It can be heat-treated and heat-hardened. It is often used for cutlery, linear shafting, and applications requiring good wear resistance. It can be hardened up to approximately RC58. However, due to added carbon in its makeup, 440 will oxidize under washdown conditions.

Stainless steels do not rust in the normal sense. If particles of red oxide appear on a stainless surface, it is most likely due to iron particulate coming from fillers within the bearing. To cleanse the surface, a solution of 10% nitric acid and 2% hydrofluoric acid at room temperature can be effective.

Aluminum and Coatings

Aluminum can be used in areas of a washdown environment where weight is a concern. However, be aware that bare aluminum has poor corrosion resistance and is susceptible to pitting and cracking. In washdown conditions, aluminum must be coated for protection. Anodizing ceramic coatings and other coatings with polytetrafluoroethylene (PTFE) or other fillers are often used, but they may not provide the resistance or life that stainless steel offers. In more caustic chemical washdown environments, stainless steel is the preferred material.

Electroless Nickel Coatings

These coatings have become increasingly popular because of their corrosion- and wear-resistance combined with a smooth, polished appearance. Some forms include a PTFE infusion to aid in non-sticking properties. Most forms of this coating are FDA-compliant as well.

Plastics, Polymers, and Fillers

These nonmetal materials tend not to have the corrosion-resistance and durability of metal surfaces such as stainless steel over time and are thus not used as often as major components in food and pharmaceutical equipment. However, due to cost, weight, manufacturability, and so on, they are increasingly being used “under the hood”— in mechanical drive components, guides, bearings, fasteners, and more. Many solid plastics, such as injection-molded bearing inserts, present drawbacks in washdown applications in that most absorb liquid, causing components to swell and increasing the potential for binding and failure.

Also be aware that each of the standards organizations covered earlier has extensive information on a wide variety of acceptable plastic materials. However, along with the base plastic, each polymeric material usually has fillers blended in by the manufacturer. These fillers are added to enhance performance, such as increased load capacity and lower coefficient of friction. Be sure that these fillers also are in compliance with standards.

Best Washdown Design Practices for Linear Motion Systems

Linear motion components offer their unique challenges in washdown applications. Rotating components need to be mounted and sealed within a limited area, but because the moving component of a bearing, slide, or actuator system travels in a linear fashion, the space needing to be sealed or cleaned will be far larger — often up to several feet larger. Below are some tips on how to minimize areas of potential bacteria buildup and maximize cleanability.

Figure 1—Bacteria tends to build up in areas that are difficult to clean, such as grooves, crevices, and between the outer shell and plastic insert of two-piece bearings.

Linear Guide and Bearing Design

For linear recirculating ball bearings, use only stainless steel–sealed bearings with compliant seal materials and approved lubrication. There are two basic types of plain bearings. When using plastic inserts, be aware of moisture absorption that will lead to the bearing material swelling. This can result in binding issues. If the inside diameter is increased to deal with swelling, this often causes loose tolerances and inaccuracies in the system.

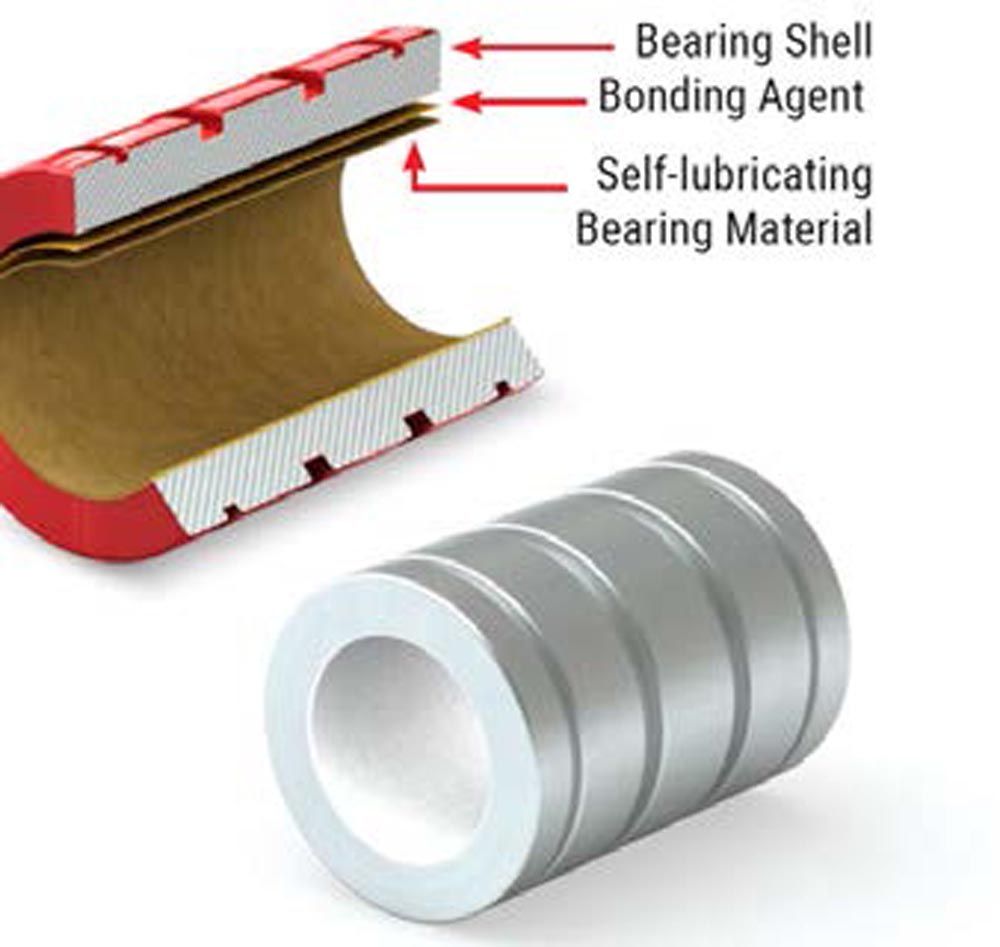

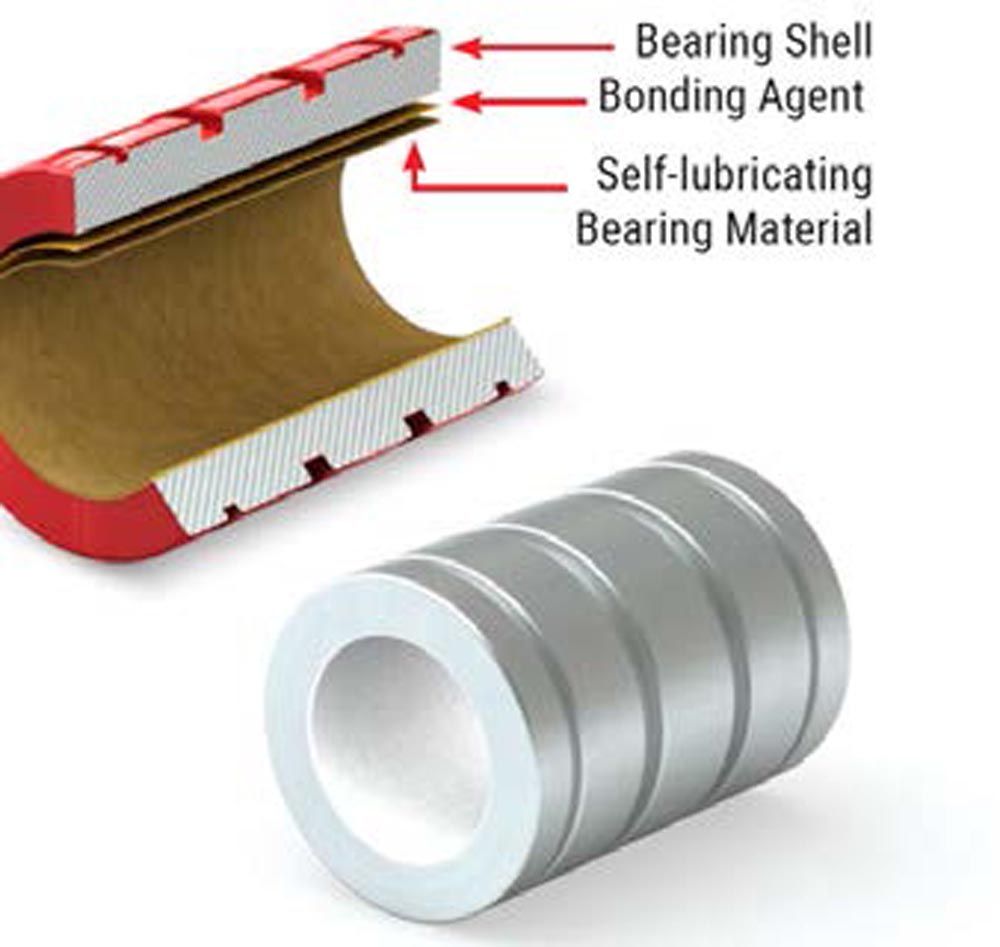

It is best to avoid open-ended bearings with grooves or inserts in areas that may be susceptible to bacteria buildup. These two-piece bearings will allow microscopic bacteria to seat in crevices, grooves, and between the outer shell of the bearing and the plastic bearing insert. One-piece bonded bearings eliminate this potential for bacteria collection.

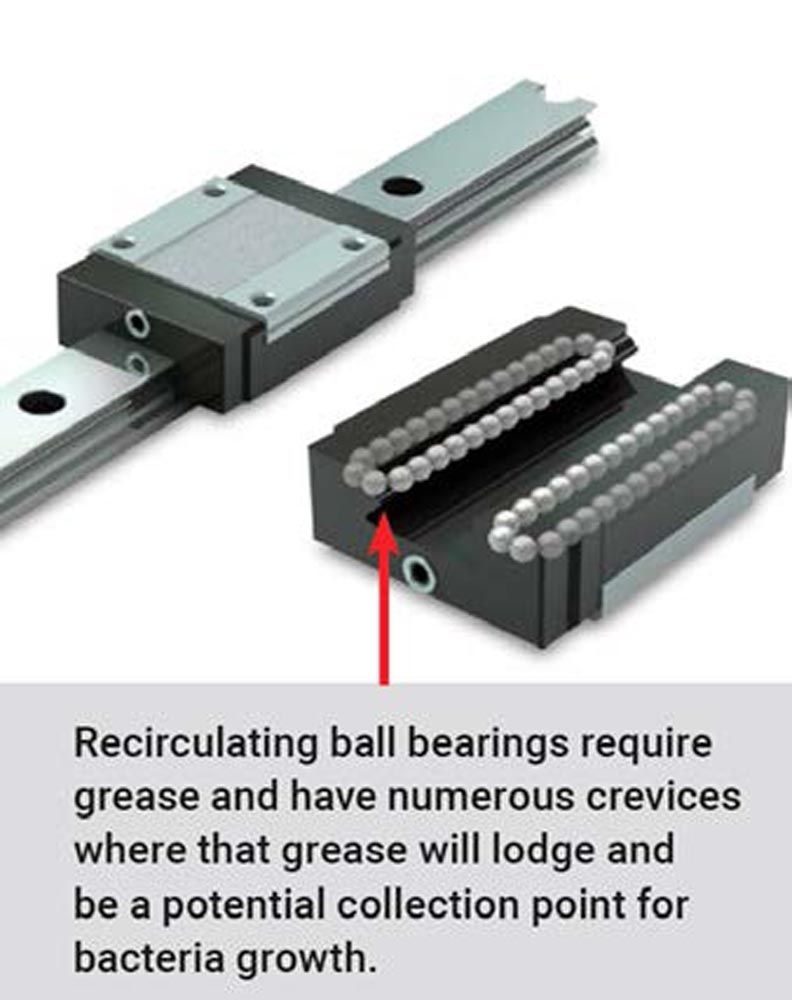

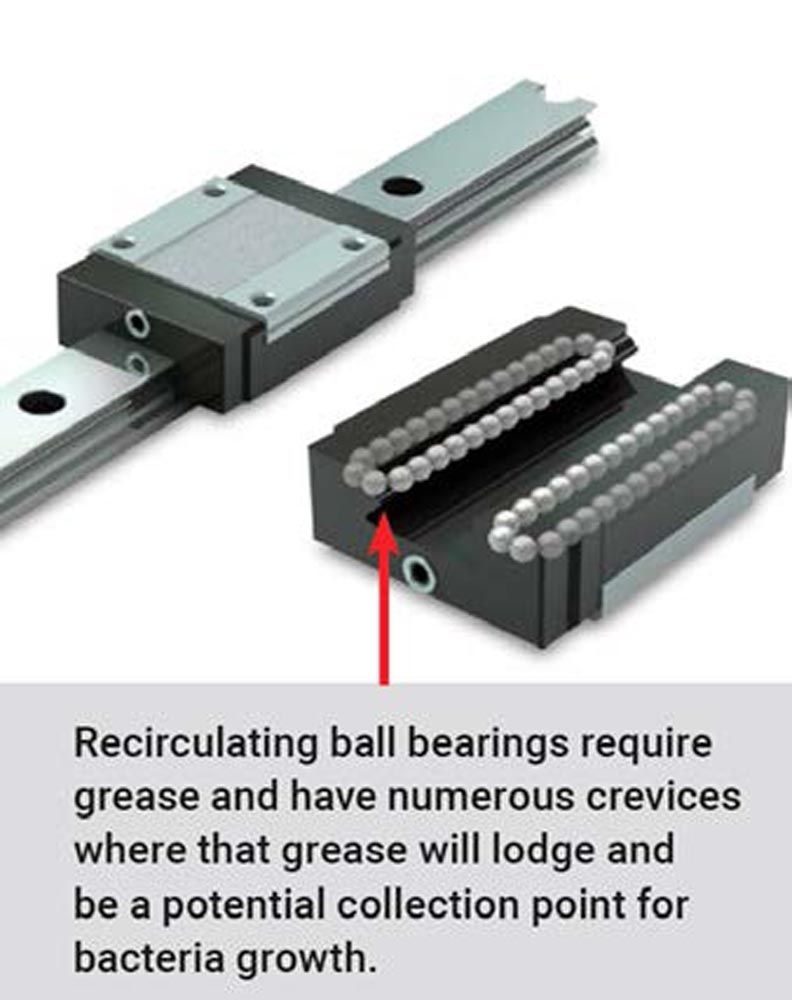

Figure 2—Recirculating ball bearings require grease and have numerous crevices where that grease will lodge and be a potential collection point for bacterial growth.

If they are to be used in a food-grade environment, ensure that materials and fillers are compliant with applicable standards.

The same design principles apply to recirculating ball bearing products, such as roundway linear ball bearings and profile rails. They provide advantages such as low friction and tight tolerances and are often available in stainless steel materials with FDA-compliant lubrication. However, they can present disadvantages in that they require grease lubrication to be used due to metal-to-metal contact. This lubrication picks up material from food items being processed, which can become trapped inside the multiple crevices and cavities around the balls and in the raceways of the bearing. This can potentially be a breeding ground for unwanted bacteria.

Figure 3—One-piece bonded bearings are the best solution for most washdown applications.

The best solution for most applications is a one-piece bonded bearing that uses PTFE-based, self-lubricating bearing materials that require no external lubrication. In addition, there are no grooves, crevices, or spaces between the liner and bearing shell where residue can become lodged, allowing bacteria to grow. The bearing material and outer shell are bonded together, creating a true one-piece bearing.

In vertical applications such as those found on in-line and carousel bottle-filling machines, it is advisable to utilize a bearing that is sealed at the top end. This eliminates contamination and prevents most of the fluid in the filling and washdown process from penetrating the bearing inside diameter. Yet it allows liquids that do get into the bearing system to easily flow through and exit at the bottom of the assembly.

Another area of concern in this type of configuration is that multiple-component subassemblies utilizing a parallel shaft design can experience bearing binding problems due to misalignment. In addition, these multiple components are also susceptible to bacteria buildup around the connectors and joints. Newer technology that incorporates dual rail load capacities and functionality into a single rail design can eliminate potential areas of contamination.

Figure 4—Bearing assemblies used in washdown environments benefit from sealing the top of a bearing to minimize the effect of washdown. Having no seal on the bottom of the bearing allows liquid to pass through the assembly.

Rail Design and Selection

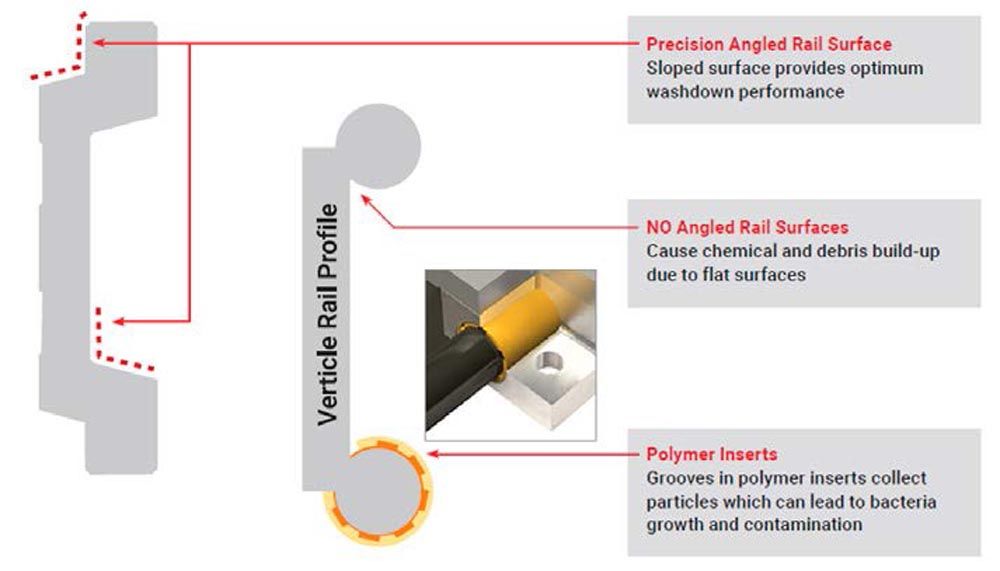

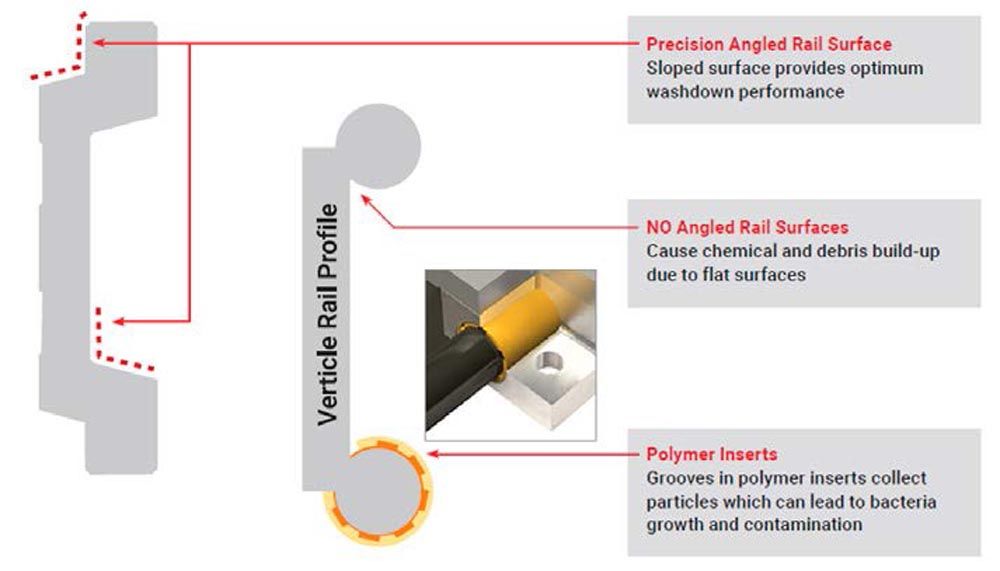

Figure 5—The sloped surfaces of precision-angled rails offer improved washdown performance by eliminating areas where particles can collect, leading to bacteria growth and contamination.

It is best to avoid as much component assembly as possible in a washdown environment. Traditional linear assemblies utilize a shaft and support rail bolted together, which are then bolted to a mounting plate or carriage. Each of these connection points creates a joint, crack, or crevice and a potential location where liquids can penetrate or where bacteria can begin to cling and build up over time.

New technology in linear motion has created slide assemblies that eliminate the need for multiple components and connectors. Unique two-piece slide systems are an ideal solution for washdown environments. In addition, these components have smoothly curved edges, without recesses where buildup can occur.

Linear Roller Bearings (cam follower style)—Typically used with a V-guide rail or as a cam follower, these bearings have internal bearing raceways that are lubricated for life and are permanently sealed with either a rubber seal or a stainless steel shield. If they are to be used in a food-grade environment, be sure the seal and lubricant are compliant with the applicable standards.

Shafting and Rails—Many different materials are available: 303, 304, 316, 440, coated aluminum, and more. Be sure that the grade selected is compatible with washdown conditions and regulations in the particular environment.

Linear Slides—These are typically twin-rail systems built up on a mounting plate. They utilize round rails or profile rails with recirculating ball bearings and have a top plate. These slides can be built with a variety of washdown-compatible materials. For food-grade applications, they can also be built up with compliant materials.

Linear Actuators—Typically, the outer housing for a belt-driven linear actuator is anodized aluminum. As discussed earlier, aluminum can be susceptible to pitting and corrosion, so these types of linear motion components are not ideally suited for washdown applications.

Standoffs

When mounting linear rails in washdown applications, especially where contamination and bacteria buildup are a concern, it is good practice to use standoffs to maximize cleanability around the linear motion system. Below is an exaggerated example of good practice when mounting with standoffs. (Be sure to calculate shaft or rail deflection when using standoffs to ensure proper operation.)

Figure 6—Using standoffs to mount linear rails in washdown applications helps reduce areas of potential particle buildup by providing easy access for cleaning behind the rail.

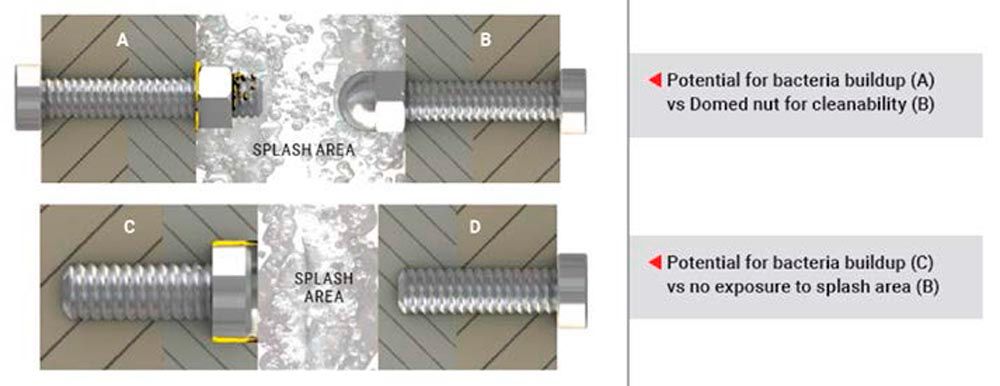

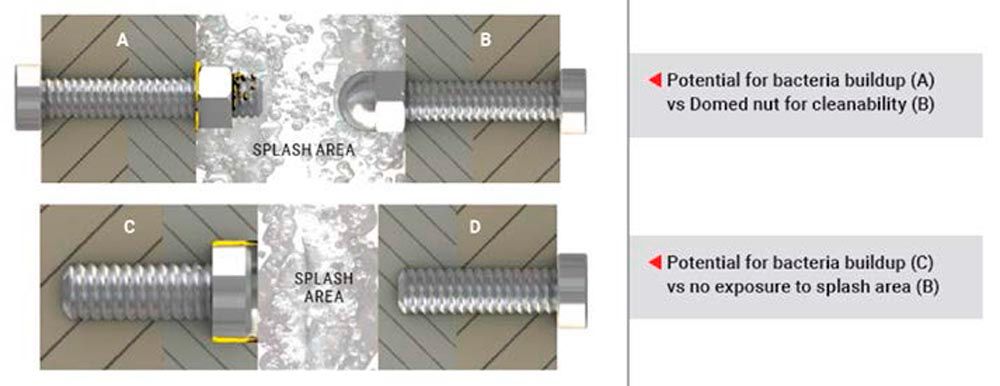

Fastener Location

When possible, avoid mounting connectors from the washdown side. They protrude and create another area where contamination can collect. It is best to bring the connector up through the bottom of the rail to be mounted. If necessary and if connectors enter the washdown area, use a domed nut for easier cleaning.

Figure 7—It’s best to avoid mounting connectors from the washdown side. Instead, bring the connector up through the bottom if possible.

Figure 8—It’s best to avoid small collection points for moisture and the potential for corrosion and bacteria buildup, such as welds exposed to the splash area. Whenever possible, radius all corners.

Location of Linear Components

Particularly in food-grade applications, it is important to consider where the linear motion device is to be mounted in relation to the food being processed. When components that are not FDA-compliant or do not meet other regulations for food contact are used over the open food path or where they can potentially come into contact with the food items being processed, risk can be eliminated by installing a stainless steel shield or cover over the components.

When constructing shields and other covers, it is important to give consideration to how the panels and plates are to be connected or welded together. Small collection points for moisture and the potential for corrosion and bacteria buildup can result from leaving the irregular surface of a weld exposed to the splash area. Whenever possible, the best case scenario is to radius all corners.

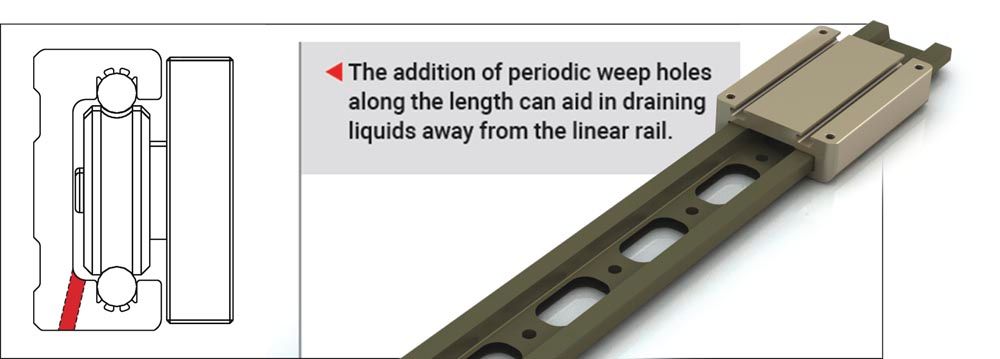

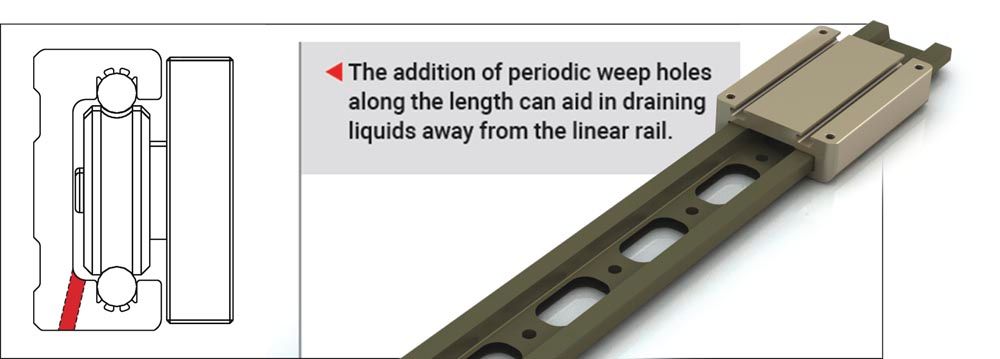

Another tactic used to manage moisture and fluids around linear motion components is to add weep holes, drainage channels, slots, or other porting features designed to channel moisture away from potential pooling areas.

The example below shows a long rail that often is mounted flat in a washdown environment. Liquids can naturally collect and pool along the length of the rail. By adding slots at strategic points along the rail, these collection areas can be easily eliminated. When combined with standoffs, this type of rail feature creates a linear guide system that is fully exposed and can be sanitized completely.

Figure 9—The addition of periodic weep holes can aid in draining liquids away from a linear rail.

PBC Linear Products for Washdown Design

PBC Linear offers a wide range of linear motion solutions for washdown and food processing applications. The key is to know your application and to match up the correct components based on the industry standards and chemical makeup of the washdown environment at hand.

RST (Round Shaft Technology) Simplicity Self-Lubricating Bearings, FL (inch)/FM (metric)—The outer shell of the standard bearing is anodized aluminum. For washdown and food-grade bearings, it is best to use the optional 316 stainless steel bearing shell. The part number is noted with an “S” (example: FLS16). Along with not absorbing water or swelling, the bearing liner materials are self-lubricating and eliminate the need for external lubrication. Not requiring lubricants, even food-grade grease and oil, decreases the amount of material deposits on the shaft surface — and the potential for bacteria buildup.

FrelonGOLD—This bearing liner has good chemical resistance but is not FDA-compliant for direct food contact (Bearings lined with FrelonGOLD and Frelon J can be used in food processing applications when they are to the side of or below the food and will not come into contact with it. If FrelonGOLD or Frelon J bearings are above food items that have not been packaged, a shield is required). It can be used in wet environments, but due to the composition of the fillers, over a period of time, surface oxidation may appear. Do not use it with deionized water. FrelonGOLD is compatible with RC60 steel, ceramic-coated aluminum, and 440 stainless steel shafting.

Frelon J (optional liner material)—This polymeric-based material is not FDA-compliant but performs extremely well in washdown and caustic applications. It is compatible with 300 series stainless steel and clear anodized shafting.

Frelon W (optional special-order liner material)—This is an FDA-compliant material that is suited for direct food contact and is available as a special-order item from PBC Linear. It is compatible with 300 series stainless shafting.

Redi-Rail Cam Roller Technology (CRT) Linear Guide—Highly resistant to corrosion in washdown applications, this rail is composed of an aluminum base with an antimicrobial powder coating. In addition, 440 stainless steel shafts are embedded in the aluminum and provide a hard raceway. The three-, four-, and five-wheel slider has 440 stainless bearings and stainless hardware for the preload adjustment feature. The seal of the stainless end caps is NSF-registered for H1 (where there may be incidental contact with food) and H2 (no direct contact with food) applications.

Commercial Rail Linear Guides—These are nonprecision, cost-effective linear guides for washdown applications. Roll-formed 304 stainless steel rails guide a three-wheel slider composed of 440 stainless steel bearings.

V-Guide System, Cam Roller Technology (CRT) V Wheel Bearings and Linear Guide Rails

For washdown applications, the V-Guide System offers 400 series stainless steel rails. The V wheel bearings are constructed of 420 stainless steel raceways and 304 stainless steel shields or nitrile rubber seals. The concentric and eccentric wheel or mounting bushings are composed of 303 stainless steel. These components can be utilized to build up a variety of linear motion configurations.

Conclusion

Whether in an outdoor environment, a simple water washdown, or a location working to eliminate bacteria and other contaminants using chemical solvent mixtures or caustics, design engineers and maintenance teams are increasingly being asked to meet difficult challenges. Selecting the right components for the conditions requires a good understanding of the environment, component life expectancy, standards, and other parameters, along with a knowledge of materials that meet these challenges and comply with regulations.

PBC Linear has experience in a variety of outdoor, washdown, and food processing applications. In addition, it offers a broad range of products that give engineers and maintenance technicians multiple options to solve problems associated with liquid and chemical interactions. By utilizing these products, application experience, and best practices for working in washdowns, predictable life for the linear motion components and assemblies can be increased.

pbclinear.com