OES Offers New Series of Gimbal Mounts

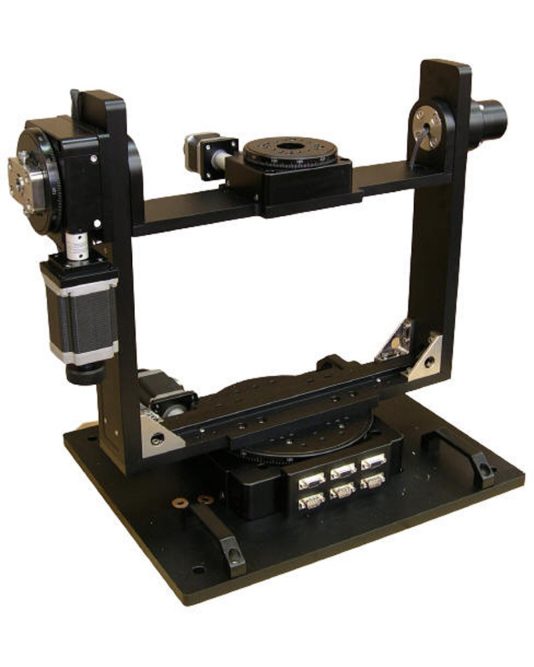

Designed for larger cameras, tracking devices, telescopes, optics, and other devices, four new, high resolution, three axis gimbal mounts have been released by OES (Optimal Engineering Systems, Inc.). This new series of Three Axis Gimbal Mounts are 588 mm wide by 463 mm high, and handle loads up to 10 kg. The AU400-AER (Azimuth, Elevation, and Roll) Series of Three Axis Gimbal Mounts feature high precision 180:1 worm gear driven “V” groove rotary stages. Each axis is capable of 360 degrees of continuous rotation in clockwise and counterclockwise directions. The position is held economically when the motor current is removed as worm gears cannot be back driven. The Roll Stage has a precision pattern of threaded holes for mounting tooling, cameras, lasers, etc., and a through hole for cables and optics. Devices up to 395 mm wide can be mounted on the rotary stage.

Motor options to power each stage include: Two Phase-Stepper Motors (AU400-AER-01), Three Phase Brushless Servo Motors with Quadrature Incremental Optical Encoders (AU400-AER-02), DC Servomotors with Quadrature Incremental Optical Encoders (AU400-AER-03), or Two-Phase Stepper Motors with Quadrature Incremental Optical Encoders for position verification (AU400-AER-04). Electrical connections are made using 9 pin DB-9 connectors.

The resolution of each stage is 0.001 degree or 3.6 arcsec with 10 micro-steps per Step Motor Driver in use. Higher resolutions and travel speeds to 45 degrees per second are possible with the servo motor options. Each axis has a HOME switch for precision initialization on power up.

An optional 360 mm x 360 mm aluminum plate with four handles and mounting holes for increased stability is available and these Three-axis Gimbal Mounts can be ordered as a complete plug-and-play system with a multi-axis motion controller, joystick, trackball, or keypad.