SEW-Eurodrive Advances Smart Automation Services

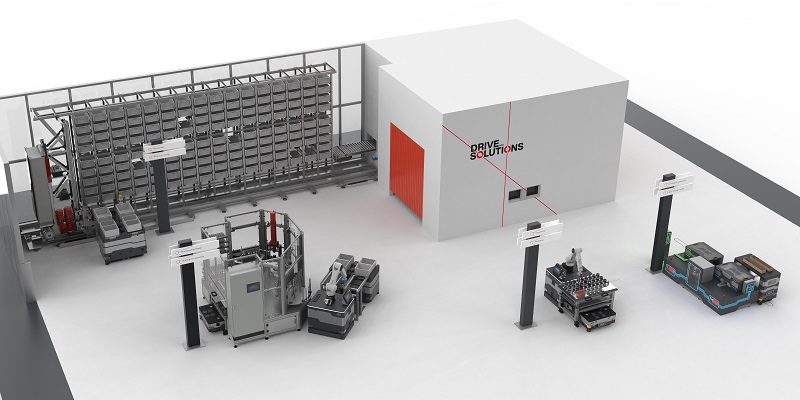

The MAXOLUTION process by SEW-Eurodrive modules in the large-scale model are intelligently networked via mobile transport and assistance systems and offer a clear insight into what tomorrow's world of adaptable production could look like. Outstanding performance can be achieved with the aid of supporting automation and future-proof material flow and logistics concepts.

The story of the production process starts at the small parts warehouse. The pioneering solutions for the storage/retrieval systems come from the MOVI C modular automation system. From drive technology, control technology, and safety technology to software and visualization, SEW-Eurodrive offers everything from a single source and to suit the relevant application.

A mobile logistics assistant – specially customized for container transport – takes the material from the warehouse to the production system for the preassembled gear unit bushings.

Mobile handling assistants help with the automated loading and unloading of machines as well as assembly and joining processes. Their various different grippers demonstrate the versatility they bring to the production environment.

The assembled parts and their load carrier are picked up by a mobile logistics assistant. The assistants utilized in the model are vehicles for transporting frames and enable an especially compact system design. Their free-ranging mobility makes them suitable for use in both complex and compact factory layouts. When it comes to packaging the assembled gear unit bushings, the vehicles perfectly illustrate a highly flexible production operation in action by merging together to form an ad-hoc process module before subsequently separating again.

One particular highlight is its vehicle concept study, which utilizes contactless energy transfer via MOVITRANS and the TES decentralized supply unit so the vehicles can run alternately on a battery energy storage module and a fuel cell based on hydrogen technology. This forward-looking project clearly shows how diverse power supply concepts for mobile assistance systems can help deliver maximum flexibility. Powered by a system that can be automatically switched to hydrogen technology, the vehicles from the concept study navigate the large-scale model just like the other mobile logistics assistants. They move freely around the space, taking care of logistics supply tasks and loosely interlinking process modules.