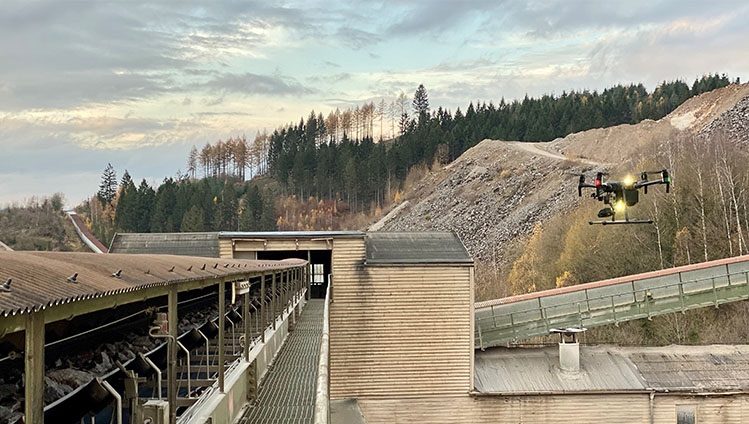

Continental Takes to the Sky for Inspection System

The CONTI ConveyorInspect Drone System helps reduce unplanned shutdowns of conveyor belts.

Continental offers the CONTI ConveyorInspect drone-based inspection system to allow operators to easily know the condition of their belts and idlers, quickly locate the exact position of failing idlers, and track changes in rotating components over time. With this real-time reporting, operators can better estimate their system’s component life and plan their maintenance. This helps prevent costly damage of conveyor system components and minimizes downtime.

As a remote, drone-based system, CONTI ConveyorInspect helps protect service technicians by avoiding time-consuming, manual inspections. CONTI ConveyorInspect provides high quality inspection data in near real time.

The CONTI ConveyorInspect system can provide autonomous visual monitoring or can be guided by a drone pilot. During automated inspections, an infrared and RGB camera-equipped drone inspects both sides of the conveyor following a preprogrammed flight routine. Once the mission is completed, the drone returns to an autonomous charging station and uploads all the relevant visual data to the cloud. With the Drone Pilot inspection routine, a certified pilot controls the drone and collects data in dangerous or hard to reach places.

Once collected, visual data is uploaded to the cloud via the ConveyorInspect portal, and the data is processed and analyzed by an Artificial Intelligence (AI) based data pipeline. The data analysis and reports can be reviewed via the ConveyorInspect app available on desktop and mobile platforms.

CONTI ConveyorInspect has been engineered and built for the demanding conditions found in mining and extraction. The drone can operate in temperatures of -4°F to 113°F while inspecting conveyors at an average speed of three feet per second. With up to 40 minutes of continuous flight and a charging time of only 40 minutes, ConveyorInspect can operate over a maximum range of three miles (5 km) and at a maximum altitude of 400 ft. (130 m). The drone is equipped with a 4K Daylight Camera and 640x512 thermal camera with a frame rate of 30FPS.

Continental Marketing Communications Americas, Rob Schulz said, “Manual belt inspections are time consuming, costly and lack accuracy. CONTI ConveyorInspect provides an ‘eye in the sky’ that scans the entire belt system. It saves time making predictive maintenance easier than ever.”