Vesconite Marine Rudder Bearings

Vesconite contributes to a communication satellite launch

The Colibri (Image credit: 2021 ESA-CNES-Arianespace/Optique vidéo du CSG—JM Guillon).

By Monique Potgieter and Deborah Spicer, Vesconite Bearings

Vesconite Bearings, through its supply of marine rudder bearings to the MN Colibri charter vessel in June, is proud to be associated with an exciting communication satellite launch that took place in September 2022. The MN Colibri has historically transported launcher components, including communications satellites, for various heavy-lift space launch vehicles, and outfitted with the Vesconite rudder bearings allowed it to transport the Eutelsat Konnect VHTS satellite, which is regarded as an important addition to global telecommunications infrastructure.

The MN Colibri transported the satellite to Pariacabo Harbour in French Guiana, near the Kourou-based Guiana Space Centre, the main spaceport of France and the European Space Agency. On arrival at the port, the Eutelsat was transported off the ride-on ride-off charter vessel. It then made its way to the launch site, where it was later successfully launched by an Ariane rocket. The Eutelsat Konnect VHTS is expected to deliver high-speed broadband and mobile connectivity throughout Europe, North Africa and the Middle East from the second half of 2023.

“Vesconite Bearings is pleased to have contributed to this momentous project,” says Vesconite Bearings marine applications engineer Monique Potgieter of the development that plans to supply European users with 100 Mbps broadband as well as to eliminate broadband black spots. “Our marine bearings are used in many intriguing shipping projects that contribute to the technological advancement of our world,” she notes.

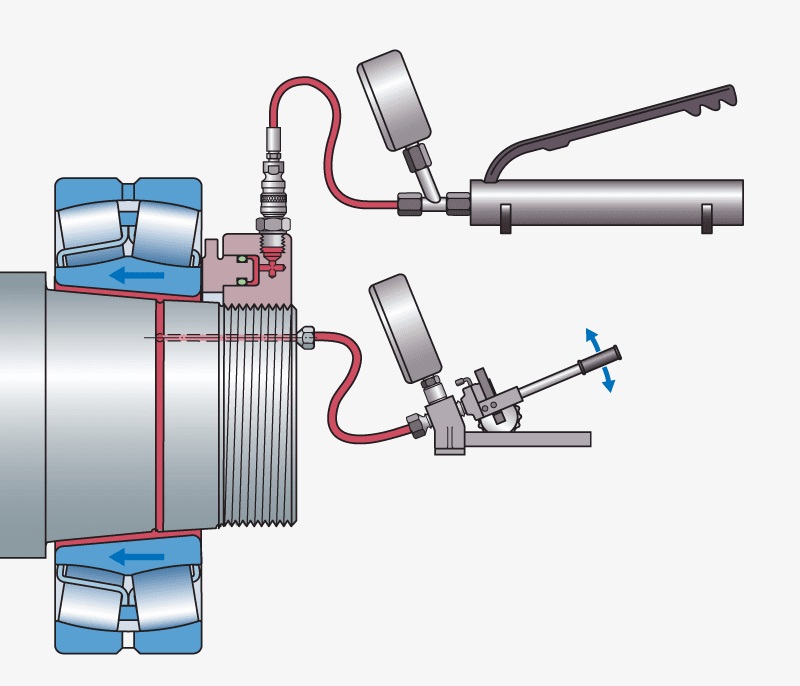

Potgieter explains that, when the MN Colibri charter ship was undergoing planned inspection, it was found that the upper and lower flap bearings needed to be replaced on the flap-type rudders. The bearing supplier was then approached by a company that focuses on rudder new builds and servicing to supply the bearings. Vesconite Bearings had the right size bushing material in stock at its Netherlands warehouse and quickly delivered the stock to Hamburg, Germany, for further machining and installation.

Material for two bearings, measuring 170 mm outside diameter (OD) x 150 mm inside diameter (ID) x 157 mm length (L) and 180 mm OD x 150 mm ID x 190 mm L, were ordered at 5 pm on June 27, 2022, dispatched just after noon on June 28 and delivered to the dry dock that did the final machining shortly after 1 pm on June 29. Marine bearings are essential to the delivery of all manner of cargo, much of which is time sensitive.

“Our team of marine specialists is dedicated to attending to urgent enquiries and we engage with ship captains, ship servicing companies and vessel managers through WhatsApp, Skype, direct calls, email and the other platforms they prefer to ensure a high level of availability, quick responses to enquiries and fast processing of orders,” says Potgieter.

The next step in Vesconite’s ability to deliver rudder bearings and stern tubes quickly is its strategy to have a large number of bearings stocked in locations around the globe and, where necessary, to manufacture these quickly at the dedicated marine bearing facility for the production of extra-large bearings.

This dedicated facility can manufacture some of the largest marine bearings in the world in one to two days using its five large horizontal lathes and two large vertical lathes.

“In the case of the Colibri, we had bearings available close to the dry dock machine shop that was working on the ship,” says Potgieter.

“We are proud that our marine-supply strategy makes us the supplier of choice for many shipyards and repair companies that trust us for fast deliveries, excellent customer service and quality products,” she notes.

Editor’s Note:

Benefits of Vesconite to Marine Applications

- Does not swell or distort in water.

- Does not delaminate or distort under higher loads.

- Does not corrode.

- Does not require lubrication.

- Is resistant to oils and fuels.

- Easy to fit and remove.

- Prolongs shaft life.