Schaeffler Showcases Innovations for Electric Motor Repair Industry at EASA 2022

FAG current-insulated bearings from Schaeffler.

Showcasing its engineering capabilities for the electric motor repair industry, global industrial and automotive supplier Schaeffler is presenting an array of advanced solutions for manufacturers and rebuilders of electric motors at the EASA 2022 Convention & Solutions Expo in St. Louis.

Describing Schaeffler’s presentation at EASA 2022, Ericka Kauer, power transmission industry director for Schaeffler in the Americas said, “Many of our customers know us as a bearing manufacturer and supplier – which is obviously very gratifying – but we’re so much more. We’re your solutions provider for electric motor applications, which means we can help you do more for your customers by improving the performance and reliability of these vitally important machines.”

Accordingly, visitors to Booth #1031 in the St. Louis Americas Center will experience a selection of precision engineered Schaeffler products, including:

Schaeffler OPTIME

OPTIME is Schaeffler’s all-new condition monitoring system that’s designed to prevent unplanned machine downtime. OPTIME monitors all your balance of plant assets across entire manufacturing facilities – seamlessly, cost-effectively and completely automatically. For just pennies per day, OPTIME provides 15,000 measurements (based on six different vibration measurements plus temperature at preset intervals) per sensor per year.

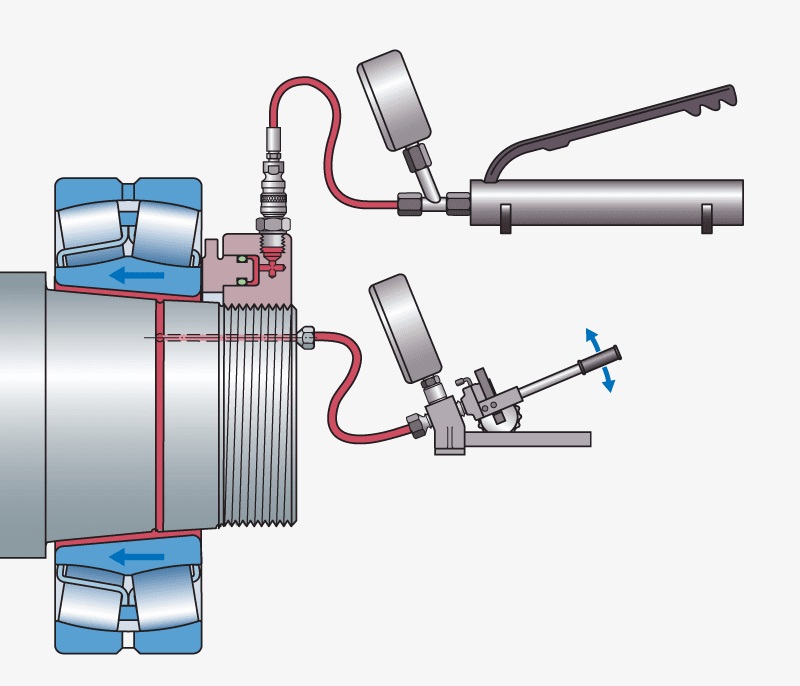

FAG Current-Insulating Bearings

Electrical current passing through bearings can lead to premature bearing failure and expensive machine downtime. FAG current-insulated bearings from Schaeffler – including hybrid ceramic or ceramic-coated versions featuring our proprietary Insutect coating – are specially engineered to stop stray electric current in its tracks.

CONCEPT1 Automatic Lubricator

Schaeffler’s CONCEPT1 single-point automatic lubricator uses an electrochemical reaction to precisely and continuously supply the proper amount of lubricant to rolling bearings inside electric motors and other industrial machinery. Easy to install and operate, CONCEPT1 can reduce plant maintenance costs by as much as 25% when compared to manual lubrication procedures.

New Schaeffler Induction HEATERS

Schaeffler’s all-new HEATER-SMART and HEATER-BASIC series of induction heaters offer installation professionals from the electric motor repair industry a broad range of applications that are perfectly suited for their specific requirements. Available in tabletop and floor-standing versions, these new induction heaters can be used to safely heat workpieces ranging in weight between 20 kilograms/44 pounds and 1,600 kg/3,527 lbs.

In addition, Frank Mignano, Schaeffler condition monitoring manager for the Americas, will be presenting – live and in person – “OPTIME: Take Off into the New Era of Condition Monitoring” on Monday, June 27, at 2 p.m. at EASA 2022’s New Solutions Theater. Session attendees will be able to learn more about Schaeffler’s award-winning wireless, cloud-based vibration technology that’s designed to identify rotating equipment issues and report them automatically to a smartphone or PC.