NORD Delivers Drive Technology for Warehouse Logistics

NORD’s warehouse solutions maximize system efficiency and provide a long service life.

The rise in ecommerce websites has led to a greater demand for warehouse automation. Technology used in warehouse logistics is extremely important as these systems must work efficiently, intelligently, and with as few breakdowns as possible to meet industry demands.

Automated storage systems are commonly used in warehouses as they offer high storage density and use agile stacker cranes for rapid retrieval and storage of goods. NORD’s solutions for these systems feature drives with precise positioning, high efficiency, compact design, and quiet operation. Highly configurable variable frequency drives provide a smart solution that is customizable for specialized applications. These VFDs include integrated positioning function, synchronous motor operation, and a physically and functionally downward compatible.

The NORDAC family of decentralized VFDs and starters are designed to be configurable for any application. The NORDAC LINK offers quick installation and servicing thanks to its quick-disconnect cable options, integrated maintenance switch, and local manual control options. NORD’s most flexible variable frequency drive is the NORDAC FLEX. With their fully scalable functions, easy parameter transfer, and modular structure, they can be tailored to all applications. The NORDAC START is a wear-free electronic motor starter for soft starting applications while the NORDAC BASE VFD has been designed as an economic variant for simple decentralized drive solutions. When combined with an energy-efficient geared motor, these VFD’s form an efficient, tailor-made solution that is ideal for warehouse applications.

Variable frequency drives such as the new NORDAC ON/ON+, offer further control with integrated PLC functionality, full Plug-&-Play capabilities, and optional safety functions. These VFDs can be wall or motor mounted, delivering versatile installation arrangements to meet application needs. The NORDAC ON also reduces the number of variants in a system due to a wide operational frequency range and integrated Ethernet interfaces. This future-ready design delivers an economic solution for IIoT environments and when combined with new IE5+ synchronous motors, produces even greater operational efficiency.

The new IE5+ permanent magnet synchronous motors (PMSM) from NORD offer one of the highest energy efficiencies on the market and significantly reduces energy consumption. They feature a compact design, flexible mounting options to meet various installation requirements, and are explicitly tailored to individual load ranges. The ventilated F-Design includes fins for a larger surface area to optimally dissipate heat while providing a high overload capacity to meet the demanding needs of automated warehouse applications such as guiding systems, chain conveyors, roller conveyors, and corner transfer conveyors. With constant torque over a wide speed range, IE5+ motors reduce the number of variants needed in a system and save on Total Cost of Ownership (TCO). NORD’s IE5+ synchronous motors are globally accepted and UL, CSA certified.

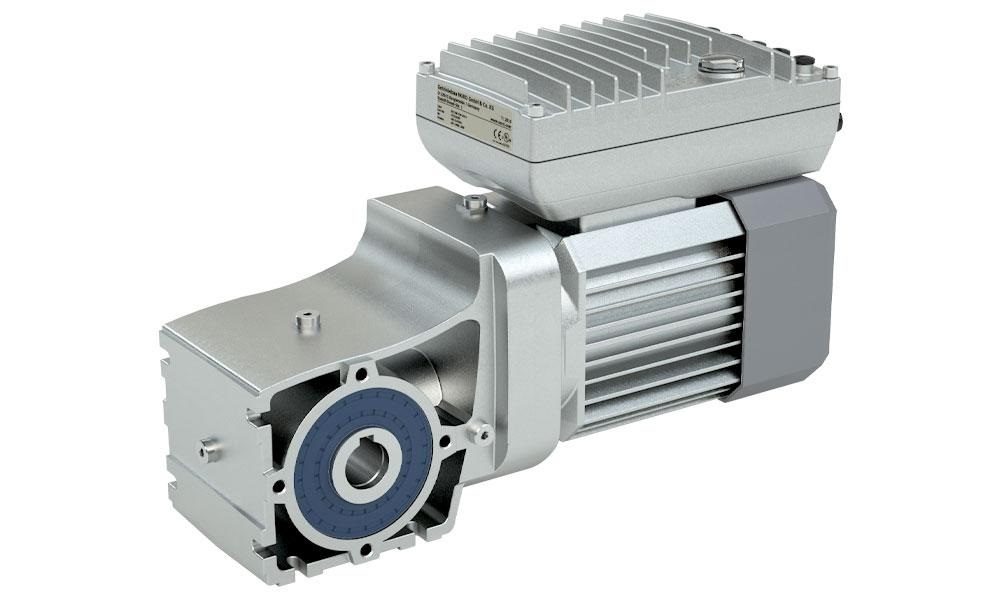

The DuoDrive integrated gear unit is a patented design concept that combines a high-efficiency IE5+ motor and a single-stage helical gear unit in a compact, UNICASE housing. These drives offer performance of 0.5 – 2 hp and an extremely high gear efficiency of up to 92% - making them ideal for intralogistics and warehousing. The DuoDrive also delivers high power density, quiet operation, simple Plug-&-Play commissioning, and fewer wear parts for low maintenance and a long service life.

NORD’s LogiDrive complete drive solution reduces planning and commissioning efforts by offering an energy efficient, standardized, and service-friendly system that is Industry 4.0 Ready! The package is comprised of a gearbox with high overload capacity, a high efficiency IE4 or IE5+ electric motor, and a variable frequency drive for precise positioning and drive control. Even at partial loads and low speeds, the LogiDrive system maintains energy efficiency due to PMSM technology – maximizing system availability and lowering operating costs. This solution can also reduce system variants through standardized geared motor selections tailored specifically to intralogistics and a large operable speed range via VFD technology.

Another specialized NORD product line for warehousing and intralogistics is the NORDAC PRO SK 500P series. This family of variable frequency drives has basic to advanced functionality in 5 case sizes to adapt to a wide range of applications. Utilizing the latest technology, these VFDs are easy to operate via a Bluetooth interface, USB interface for parameterization, and an SD memory card for storage and transfer of parameters, firmware, and operating data. An integrated multi-protocol Ethernet interface allows for quick connectivity to Ethernet-based control systems and can be configured to precisely adapt the drive to the application requirements. NORDAC PRO VFDs can also be programmed to control conveyor systems section by section, effectively managing flow during heavy traffic periods to prevent blockages and backups.