JW Winco Expands Coupling Portfolio

JW Winco's coupling portfolio has expanded for a variety of applications.

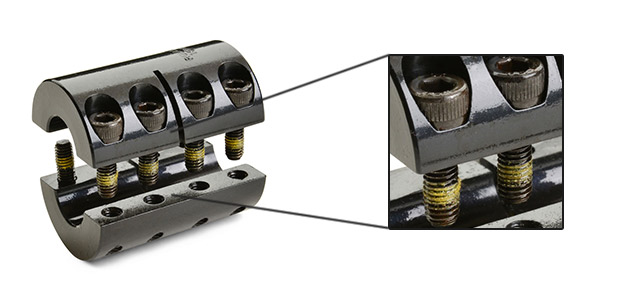

Couplings from JW Winco transmit rotary motions and torques from shaft to shaft. They also even out tolerances and mechanical deflection that would otherwise result in damage to drive or measurement configurations.

JW Winco recently added couplings of aluminum and stainless steel that include designs for positive and non-positive connections. Multiple bore diameters, various, stiffness and hardness levels of the coupling body as well as an optional keyway allow very specific customization to the given use case. In general, all couplings compensate for offsets and misalignments, accommodate runout error and axial motion, and dampen vibrations and impacts to varying degrees.

At the application level, there is a choice between position and motion control or torque and power transmission.

For position and motion control, the rotary motion must be transmitted with very high precision and accuracy. This requires a coupling type that functions with zero backlash in the direction of rotation and has high torsional stiffness. Typical applications include servo and stepper motors for linear axes, industrial robots and test benches.

For torque and power transmission, on the other hand, the focus is on pure force transmission. This calls for couplings that can withstand high torques and heavy loads while functioning reliably in harsh conditions. Typical applications include conveyor systems, pumps and agitators, packaging machines.