Transforming the Drivetrain

A Look at the Mobile Machine Market in 2022

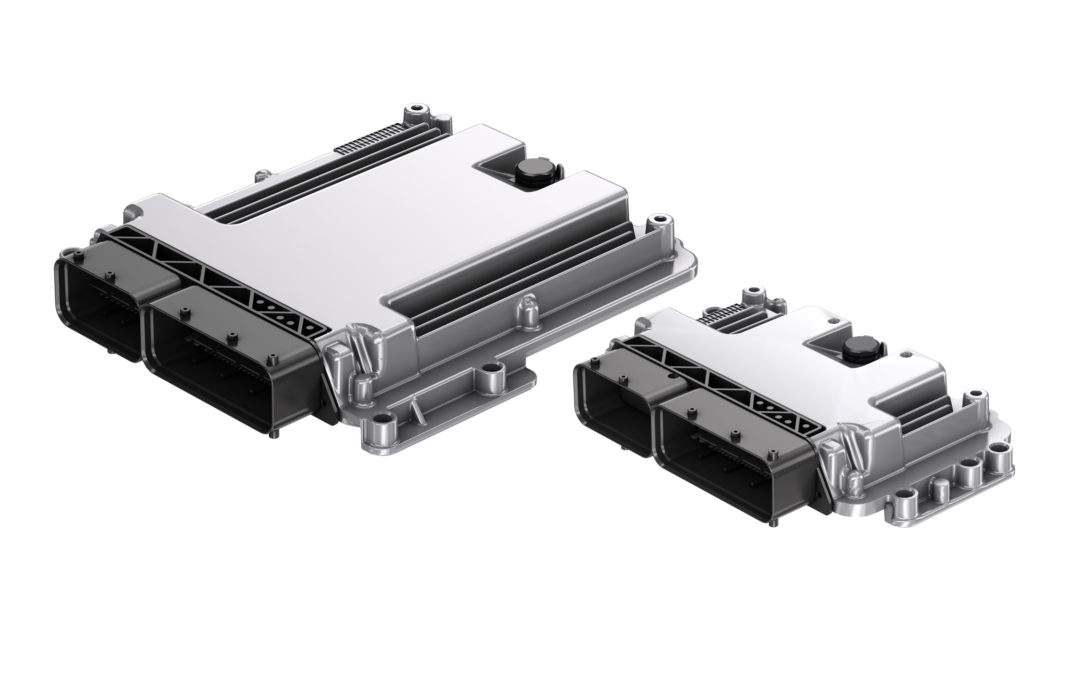

BODAS RC controllers from Bosch Rexroth.

The mobile machine market encompasses equipment supporting the movement of materials and components. This includes agricultural machinery, construction vehicles, municipal machinery, etc. These non-road mobile vehicles—tractors, cranes, forklifts and material handling equipment—often require personalized solutions focused on machine safety, automation and electrification.

Manufacturers today are merely scratching the surface when designing electric drive equipment for these challenging environmental applications. The end game is to create a modular, scalable platform that provides motor-generators, inverters, gearboxes, software and matching hydraulics to meet mobile machinery demands.

“As with any industry, the adoption of new technologies is challenged by technical know-how, proper support infrastructure, and resources for implementation and market deployment. Hydraulics and gears are very well-known components in the off-highway market that have already been revolutionized with the advent of electronic controls,” said Enrique Busquets, director, product area electronics and electrification NAM at Bosch Rexroth.

What customers both want and need today are systems that can be easily deployed to fit each unique mobile application, according to Busquets. Bosch Rexroth, for example, has spent decades to provide a scalable, mobile hydraulics portfolio that goes beyond restrictions and boundary conditions.

Growing Trends

Electrification in this market mirrors the automotive industry. Areas like climate change, urbanization, and stricter energy regulations are forcing the mobile machinery market to look closely at exhaust, emission and noise reductions as well as an increasing demand for renewable energy sources.

Matthias Kielbassa, vice president electrification at Bosch Rexroth, discussed the importance of scalability, robustness and functional safety when introducing a line of components for the electrification of mobile working machines called the eLION platform. Kielbassa said that the eLION developers relied on the company’s own experience with electrical industry solutions and its comprehensive knowledge of the mobility sector throughout the development process.

An Electrification Platform

Bosch Rexroth’s eLION platform includes the electric 700 V eLION motor-generators covering a nominal power range from 20 to 200 kW (peak power up to 400 kW) and nominal torques of up to 1050 Nm and maximum torque of up to 2,400 Nm. Additionally, eLION offers inverters in various power classes with up to 300 A continuous current and high overload capacity.

Bosch Rexroth eLION platform inverters are available in various power classes.

Bosch Rexroth eLION platform inverters are available in various power classes.

Gearboxes with high power density for hub and central drive configurations (eGFT and eGFZ) are also part of the eLION portfolio and allow compact drive units for a wide range of applications. BODAS software modules—for controlling mobile machines—are available for the entire eLION platform, along with matching hydraulic components such as axial piston pumps.

Other electrical components include DC/DC converters, power distribution units, on-board chargers and high-voltage cables. Manufacturers can rely on integrated solutions, irrespective of the energy source.

“For electrics, the challenge is formidable. From the development of efficient, compact, scalable, functionally safe, and reliable components to the pairing of each component with the appropriate accessories and software to allow the system to operate at its best. For that reason, the eLION portfolio has been developed with the highest flexibility, functional-safety-ready software at the component level, and specifically developed based on off-highway specifications,” Busquets said.

With regards to electronics and IoT, the know-how on the application level and expertise on architecture design and functional safety has been central to software development. BODAS (Bosch Rexroth Digital Application Solutions) software, for example, can examine drive control for wheeled vehicles, travel control for track drives, valve control, control solutions for hydraulic systems and more. This package stands for the company’s entire portfolio of IoT solutions, software and electronic hardware for the off-highway market.

“These solutions significantly speed customers’ machines time to market while operating at the highest levels of safety and security,” Busquets added.

For electrics, Bosch-Rexroth’s portfolio is a combination of decades of industrial applications expertise and an innovative approach to the design of each component based on specific requirements for the off-highway market. This give and take wouldn’t be possible without the company’s experience in factory automation.

People who work in different parts of Bosch Rexroth regularly collaborate with each other, according to Kielbassa.

“The factory automation division, with its deep technology expertise in electrics, contributed a lot to the development of our new electric motors and inverters. The ISO 13849 norm for functional safety, for example, applies for factory automation and for off-highway vehicles as well,” he said. At the core of Bosch Rexroth’s experience is automotive and commercial vehicles. That means there are Bosch business units with a lot of knowledge in powertrain technology, a unique advantage to have when developing systems for the mobile machine market.

Busquets said that the eLION portfolio has already made an impressive impact in the off-highway market for 2022. “Customers around the world and especially in the United States have experienced the total transformation of their machines. We expect this trend to continue strongly as the year progresses.”

Future-Viable Equipment

The eLION motor-generators and inverters are highly robust: both comply with the IP6K9K ingress protection requirements and can be used at a temperature range between -40 °C and 85 °C. The maximum temperature for the motor-generators is as high as 100 °C. The shock and vibration resistance of the eLION components is up to 50 g for shock and 10 g for vibration. A particular focus during product development was on functional and electrical safety. Manufacturers and users benefit from inverter safety functions in accordance with industry standards.

The eLION motor-generator focuses on functional and electrical safety.

The eLION motor-generator focuses on functional and electrical safety.

“Functional and electrical safety are not only at the core of the eLION and mobile electronics portfolios but also of every developed solution at Bosch-Rexroth. These aspects are crucial to overcome the challenges related to the adoption of this new technologies in the off-highway market and ultimately gives customers the highest degree of confidence when developing and deploying their next generation machines in the market,” Busquets said.

Higher efficiencies, lower noise pollution and less air pollution will certainly help customers strengthen their mobile machinery technologies in the future.

“Our efforts will continue toward developing products for the future and exploiting the potential of our extensive portfolio through the power and flexibility of software and electronics,” Busquets said.