Concepts NREC Announces Latest Release of Agile Engineering Design System

Concepts NREC is pleased to announce the release of v2022.0 of the Agile Engineering Design System, with a special focus on improving rocket engines. The Agile Engineering Design System is an integrated suite of software modules for Computer-Aided Engineering (CAE) and Computer-Aided Manufacturing (CAM) specialized for turbomachinery.

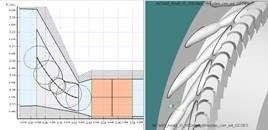

Among the dozens of new CAM capabilities in v2022.0 of MAX-PAC is the introduction of probing operations for on-machine probing or CMM formats. MAX-PAC also now supports customization of standard toolpath files. Predefined strategies can, for example, combine roughing and finishing operations into one alternating path, or you can create your own strategy using individual passes from one or more operations.

Rocket turbopump design was the focus of enhancements in the CAE suite. On the turbine side of the shaft there is now a streamlined system for the design and analysis of drilled nozzles from meanline through CFD. On the pump side we have taken many of our in-house design methods for secondary flow paths and built them into the Agile system, from meanline through CFD, as well as improved the automated meshing of inducers.

In addition to the rocket turbopump improvements, v2022.0 of the CAE suite includes enhancements to every module. Some of the highlights are the ability to optimize secondary flow paths and seals parametrically, as well as improvements to automated CFD optimization to detect convergence and new real-fluid modeling.

Dr. Peter Weitzman, president of Agile Engineering, noted that “2021 represents a new normal for the Concepts NREC software business. We have fully adjusted to developing software from our home offices around the world and are quite proud of this new release which will allow our customers to develop better products. We have also increased staffing to improve technical support and training for our new and existing users."

Version 2022.0 is available now for active Agile Product Support (APS) members to download.