Renk AG Offers Intelligent Solutions for Wind Turbines

At WindEnergy 2018 in Hamburg, Renk AG presented two product innovations with the EQ-Gear gearbox and the EQ-Flex couplings. The gearbox with the unique slide bearing technology allows for tremendous power density due to the ideal load distribution. Special materials as well as innovative coating procedures ensure optimal operation. In addition, Renk presented the VIB-Monitor and test systems for wind turbines. Trade visitors were able to look around in a wind turbine gondola with a virtual reality training system and experience Renk drivetrain solutions live in operation.

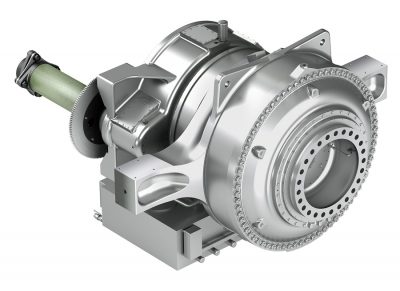

For more than 30 years, Renk has been offering complete solutions in the form of gearboxes, couplings, slide bearings and test bench technology for wind power. The intelligent planetary bearing system of the new EQ-Gear gearbox thus ensures almost uniform load distribution in all operating conditions. As a manufacturer of gearboxes and slide bearings, decades of experience in mastering extreme forces allow Renk to establish wear-resistant slide bearings as a sustainable alternative to conventional rolling bearings. There is no service life restriction thanks to the optimal design. At the same time, the modular design allows for economical solutions for virtually any application.

EQ-Gear: Variable use for all platform configurations

The EQ-Gear is suitable both for low and medium-speed platform configurations in coaxial design as well as for the high-speed drive train with an axially-offset generator connection. Especially in the coaxial platform configuration, the lines required for pitch control can easily be guided through the gearbox between the input and output shaft. The unique wireless temperature monitoring is ensured by the remote monitoring of slide bearings. The optimal load distribution between the planetary stages is self-adjusting. Optionally, the entire system, including the electrical connection, can be tested and validated in the test bench. The gearboxes are certified according to IEC and GL guidelines.

EQ-Flex: For reliable torque transmission between the gearbox and generator

The torque limiter of the new EQ-Flex coupling ensures the torque limitation in the event of overload. This increases the system availability and the operators benefit from the freedom from maintenance and wear stability. The patented slip system ensures a variable and stable slip torque during operation. It is possible to adjust the slip torque without disassembling the coupling in the drive train or to re-calibrate in the test bench. The layered structure on the specially shaped discs compensates axial, radial or angled offsets between drive and work machines without generating large restoring forces. The torque is measured continuously.