GKN and Stackpole Receive PM Design Awards

Winners of the 2018 Powder Metallurgy Design Excellence Awards Competition, sponsored by the Metal Powder Industries Federation (an international trade association for the metal powder producing and consuming industries), were announced at the PowderMet2018 International Conference on Powder Metallurgy & Particulate Materials. Receiving grand prizes and awards of distinction, the winning parts are outstanding examples of PM’s flexibility to push forward new concepts and process controls and demonstrate the inexhaustible well of capabilities PM can marshal in the service of component design. Designers continue to choose PM for critical applications such as auto engines and transmissions, medical devices, consumer products, military applications, and more.

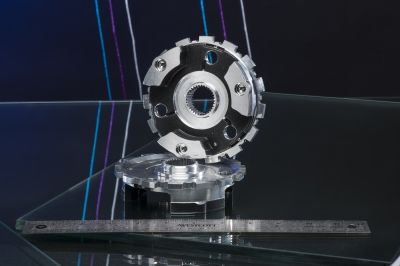

The Grand Prize in the Automotive—Transmission Category was awarded to GKN Powder Metallurgy for an aluminum planetary reaction carrier made for General Motors. The carrier goes into the all-new GM 9T50 9-speed transmission offered in such vehicles as the Chevrolet Malibu and the Equinox crossover. Compacted of a unique metal-matrix-composite (MMC) aluminum alloy system and mated to an overdrive carrier, this first-of-its-kind two-piece design required industry-first tolerances.

GKN Powder Metallurgy won a second Grand Prize in the Automotive—Engine Category for a copper steel main bearing cap made for FCA US LLC. The part is used in the 2.0 L all-aluminum turbocharged four-cylinder FCA engine launched in the Alfa Romeo Giulia. While powder metal (PM) main bearing caps have dominated engine design for more than two decades, the design of this part breaks new ground. Requirements for engine weight reduction drove the designers to an “upside down” sculpted version. The novel design delivers a part that is 23% lighter than previous versions and offers a 10% better fatigue strength.

In addition, an Award of Distinction in the Automotive—Transmission Category was given to Stackpole International, Canada, for a copper-steel rear planetary carrier made for Ford Motor Company. It’s used in the new 10-speed automotive transmission developed by Ford jointly with General Motors that was launched in such vehicles as the Ford Mustang and GM Camaro. The assembly consists of a clutch hub and a spider, which are joined using a novel sinter-brazing concept. The creative design of the ferrous carrier enabled it to win out over an aluminum casting design by delivering lighter weight and superior strength.