Varvel Produces Custom Gearboxes in addition to Standard Offerings

The Varvel Group can produce custom gearboxes to satisfy specific needs including a gearbox developed for an American customer that produces automatic machines for indoor entertainment.

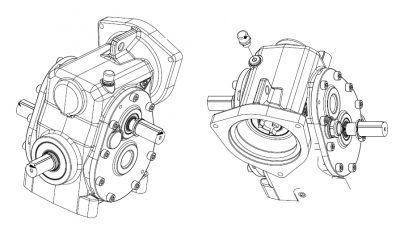

Varvel provided 1,200 units for this particular application. These gearboxes were specially designed to eliminate the problem of oil leaks as well as the inconvenience caused by machine downtime, high maintenance and part replacement costs. The gearbox provides continuous duty for 12-18 hours with frequent interruptions of only a few minutes. Its hybrid structure combines the characteristics of a worm gear, a parallel shaft gearbox and a bevel helical gearbox. The input stage resembles a worm gearbox, driving three output shafts via a special geartrain. In addition, it is suitable for use with 50 or 60 Hz single phase motors.

This unique gearbox demonstrates Varvel's expertise in customization. These tailored solutions can vary from simple modifications to standard gearboxes to the design of completely new products based on unique technical solutions, tailored to satisfy specific requirements and to solve specific problems.