Drive Lines Space-Saving Gearheads Reduce Backlash

Promising maintenance-free, long life operation with a highly compact design, the SWG gearhead can be specified with precision of better than 1 arc minute (arc min).

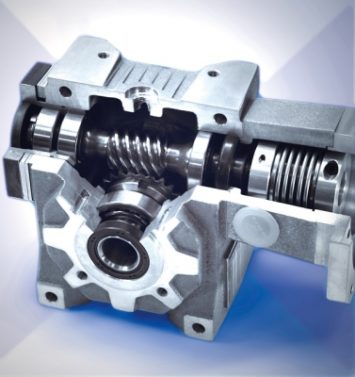

Designed to be compact and lightweight through a combination of right-angle design and a cast aluminum-magnesium alloy body; the SWG ensures high torsional stiffness and high permissible overloads, as well as reducing noise to less than 55 dB for near-silent operation.

The SWG is available with three levels of precision: a standard version offering better than 10 arc min, a precision version offering better than 3 arc min, and a high precision version offering better than 1 arc min. This exceptionally low backlash performance makes the SWG suitable for use in the most demanding servo applications.

The gearhead employs an extra wide worm wheel for higher loads and increased torsional stiffness. The manufacturer has developed a special computer optimized gear contact pattern that ensures less stress and longer life. Indeed the SWG is rated for a lifetime of 25,000 hours.

A combination of taper roller bearings and floating ball bearings on the input eliminates the need for adjustment due to preload, and permits higher input speeds of up to 6,000 rpm. The double taper roller bearing gives the gearbox higher stiffness and reduces vibration, while the floating ball bearing allows the worm shaft to expand as temperature increases, eliminating side load and improving service life.

In addition, the use of oversized taper roller bearings on the output shaft maximizes radial load capacity. The SWG range covers 11 gearbox sizes from SWG 30 to SWG 4800, with input shaft diameters from 14 mm to 100 mm and torque ratings from 29 Nm to 7833 Nm. Gear ratios are available from 5.125:1 up to 90:1. Output options include single and dual output shaft, hollow shaft with keyway or shrink disc, and robot flange.