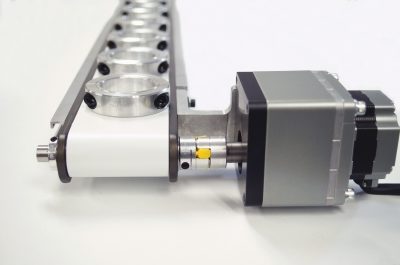

Ruland Jaw Couplings Utilized for Precision Conveyors

Ruland zero-backlash jaw couplings have a balanced design, accommodate all forms of misalignment and have high dampening capabilities, making them an ideal fit for precision conveyors with frequent starts and stops. These conveyor applications are often found on equipment used in semiconductor, solar, optical inspection, and medical automation. Jaw couplings offer system designers a wide range of sizes and performance characteristics to fit their application requirements.

Zero-backlash jaw couplings from Ruland are made from two polished aluminum hubs and a spider type insert. The curved jaw profile of the hubs press fits to the spider, ensuring zero-backlash operation. Hubs are available in clamp or set screw style with inch, metric, keyed, and keyless bores. Spiders are available in three durometers: 98 shore A for high stiffness, 92 shore A for a balance of stiffness and compliance and 85 shore A for the highest amount of dampening. Conveyor designers can mix and match hubs and spiders to create a coupling that best fits the need of their application.

Ruland jaw couplings have a standard balanced design for reduced vibration at higher speeds which is critical for conveyors in applications such as rapid optical inspection where errors can be caused by slight deviations in expected positioning. Jaw couplings are considered fail safe because if the spider fails, the jaws on the two hubs will interlock with no loss of power transmission. This prevents the system from coming to an abrupt stop and damaging sensitive high value items such as semiconductor or solar wafers.

Ruland jaw couplings are made from bar stock sourced from select American mills and carefully manufactured in Ruland’s factory in Marlborough, Massachusetts. They are available in bore sizes ranging from 1/8 inch to 1 1/4 inches or 3 mm to 32 mm. Stainless steel hubs and spiders with a center hole are available by request.