Mayr Develops Braking Systems Equipped for Industry 4.0 Challenges

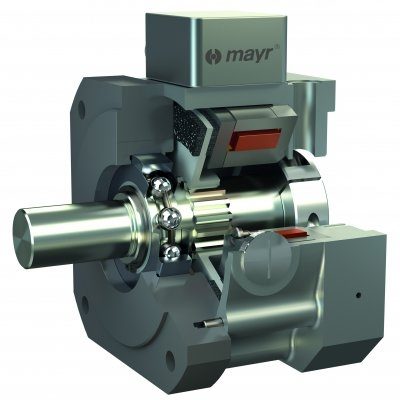

Mayr Power Transmission offers a brake system with modules including the ROBA-brake-checker or the ROBA-torqcontrol that allows permanent brake monitoring. The ROBA-brake-checker module, for example, monitors the switching condition as well as the tension path or tension force reserve without sensors and detects safety-critical changes in voltage, air gap and temperature. As a result, significantly more processes are depicted during the safety brake monitoring than was previously the case. On reaching the tension path reserve, the ROBA-brake-checker therefore sends a warning signal indicating that the brake can continue to be operated for a certain amount of time at an early stage. During this time, the machine owner can undertake targeted maintenance – in coordination with their work process. In addition, the module also simultaneously assumes the control of the brake and therefore replaces a rectifier. Switching condition monitoring and brake controls are thus combined in one device.

The developers have also successfully created a new friction lining technology through which the brakes achieve even further-improved torque consistency and a higher performance density. Under certain circumstances, a smaller, lighter brake construction size can be selected for higher braking torques and for brakes, on which higher demands are placed. This takes into account the general trend for machines and their components (engines, for example) to be increasingly more compact in construction and with greater performance density.