Thomson Expands Miniature Metric Ball Nut Styles

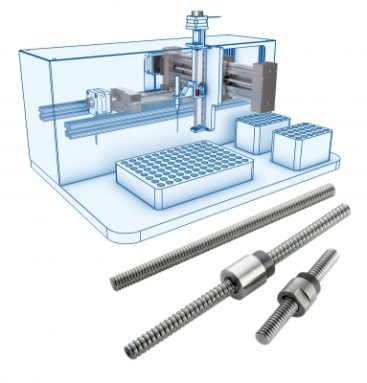

Thomson Industries, Inc., a manufacturer of mechanical motion control solutions, has built upon its selection of miniature metric precision ball screws to include three common interface styles: flanged, threaded and rounded. This comprehensive offering equips customers with even more options when designing small-space applications. These metric ball screws deliver a host of performance, supply chain and pricing benefits for users seeking smooth, quiet operation and best-in-class load capacities and lifecycles.

Joining the family’s threaded style (TSI) mounting interface are flanged (FSI) and rounded (RSI) styles, which benefit from a unique multi-liner ball return system that provides smooth operation and increased load capacity. Ideal for laboratory, medical and mechatronics components, the miniature metric ball screws are available in a wide range of standardized diameters (Ø6 mm – Ø14 mm) to create a truly flexible solution. Though small in stature, they have been known to achieve twice the capacity of comparable models in most sizes.

With North American manufacturing and logistics, Thomson is able to provide customers with shorter lead times and lower-cost logistics. “Our state-of-the-art production facility precision-manufactures ball screws that help our customers design faster, safer and more optimized products for their customers,” said Jeff Johnson, global product line manager – screws for Thomson. “We’re also able to custom-machine screws and nuts within a matter of weeks to help meet customers’ tight production schedules.”