Iwis Pin Oven Chains Expand Product Line for Transporting Beverage Cans

For the conveying of thin walled tubular sections, such as beverage cans around the production process, Iwis offers a range of pin oven and tube transport chains. The new versions will be available are now available with its latest addition being the POChain-I.

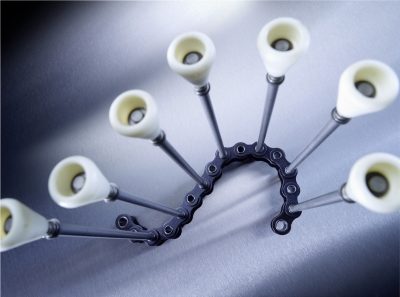

Developed specifically for conveying drink cans, Iwis pin oven chains are wear-resistant and feature precision roller chains fitted with transport pins and replaceable protective pin heads. They are designed to transport thin-walled hollow bodies at high speeds at ambient or elevated temperatures with exposure to various media throughout the production process. Pin oven chains are used in the beverages industry and wherever cans or other thin-walled hollow bodies need to be conveyed, printed, painted or dried.

The standard chain size is M128ASL. Other versions, for example with a corrosion-resistant coating or maintenance-free chains, are also available on request. In the standard configuration every seventh pin is hollow to accept the transport pins. The chains can be tailored to include other pin spacings depending on the nature of the conveyed goods. The length of the transport pins can also be adapted and range from 184 mm to 214 mm in length from the chain’s longitudinal axis to the head.

The transport pins that hold the product are fitted in hollow chain pins at defined intervals and secured with self-locking nuts (POChain-P) or an additional lug and split pins (POChain-S). On models POChain-P and POChain-S, transport rods can be individually replaced in-situ – for example if they are worn or damaged – by releasing the nut or removing the split pin. The chain does not need to be separated or removed from the machine, which saves maintenance time and ensures that the chain outlasts its attachment parts. Versions POChain-P and POChain-S of the split pin oven chains also feature predefined fracture points in the transport pins that prevent damage in the event of a collision.

The latest addition to Iwis’s range of pin oven chains is labelled POChain-I and features a cost-optimized design. All versions of the POChain have spring-loaded protective heads on the transport pins to protect the conveyed hollow objects (Fig. 2). These heads are made from a high-temperature resistant thermoplastic, which offers chemicals resistance at temperatures of up to 260 °C.

All POChains are supplied with a lubricant designed for use at high temperatures and chain speeds, and is resistant to various corrosive substances. The transport pins are also available with special-geometry and fixed protective end profiles to suit any conveying application (Fig. 3).

In addition to pin oven chains, Munich-based chain specialist Iwis provides a full product range for all drive and conveying applications. This also includes precision and high-performance roller chains, conveyor chains, maintenance-free and corrosion-resistant chains, power and free conveyor chains, special-purpose conveyor chains, flyer chains, flat-top chains, modular belts, chains and accessories for agricultural machinery, and timing drives for the automotive industry.