Festo Introduces All-in-One Servo Motor and Drive Unit

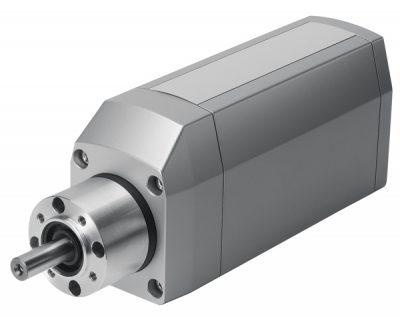

Festo, a manufacturer of pneumatic and electromechanical systems, components, and controls for process and industrial automation, recently introduced its all-in-one servo motor and drive unit: the MTR-ECI.

The MTR-ECI integrated motor is designed for automating manual changeovers. With standard stainless steel shaft, IP65 protection class rating, and food grade lubrication, the MTR-ECI is designed for a variety of motion actuation applications and environments.

The MTR-ECI features a brushless motor, integrated gearbox, power electronics, controller, absolute encoder and EtherNet/IP interface. The MTR-ECI does not require a cabinet and is suited for on-machine mounting and fast, precise positioning during product changeovers, adjustments to conveyors, paper or foil cutting, and other format adjustment applications.

Less wiring is needed for this integrated motor and drive. The unit only requires a voltage supply and a fieldbus or multi-pin connection. Communication connectivity to Rockwell PLCs via EtherNet/IP simplifies integration within the Rockwell control architecture.

Complete commissioning can be performed using simple teach-in functions. Built-in electronics can store up to 16 pre-configured motion profiles (position and speed). Both acceleration and deceleration parameters are pre-configured and applicable to all motion profiles. Homing can be accomplished with a sensor or against a hard stop.

Power is provided by a 24V/48V DC supply. Nominal velocity and torque ranges up to 592 rotations per minute. The low power setting adds to the safety of the changeover process. The integrated multi-turn absolute encoder eliminates the need for homing the machine on startup.