The Efficient, Evolving Technology of the Gearbox

The Efficient, Evolving Technology of the Gearbox

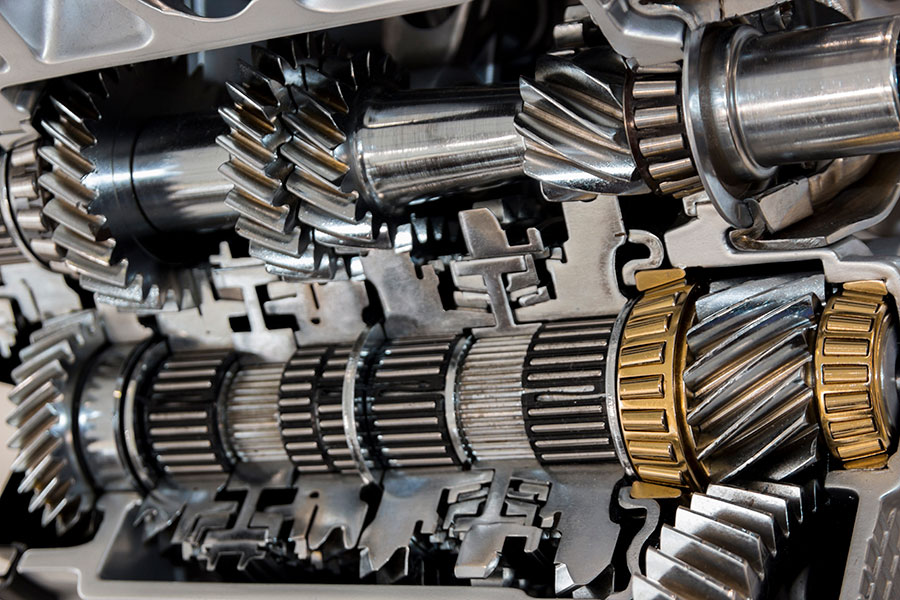

There is always some element of maintenance, replacement, and monitoring required when it comes to factory equipment; however, there are some components, which need much more than others. Gearboxes are one type of high-maintenance components. These are typically items, which face significant wear due to their unique job of converting high speed, low-torque power from electric motors into the low-speed, high-torque power necessary for machinery.

Despite the downside of being high-maintenance, gearboxes continue in their prevalence because, as the axiom in the power-transmission industry states, according to Machine Design, “Speed is cheap, torque is expensive.” Furthermore, being dependent on motors to produce the torque demanded by many loads (known as direct-drive technology) is typically less economical than developing the torque via a motor/gear reducer duo. For this reason, most engineers cite gearboxes in their layouts. Gearboxes, also, can render other mechanical parts redundant, such as bearings, belts, pulleys, and chains. These omissions can streamline and contribute to the making of more cost-efficient motion-controlled operations.

Engineers must employ the most efficient gearbox, which suits their application’s needs. Using an apposite gearbox is both economical and environmentally wholesome. Suitable gearboxes also need to generate less power losses, so designs can use cheaper, compact motors, which don’t require as much space. A reduction of heat generation is also a byproduct of efficiency; this will extend the longevity of a gear reducer as well as the oil in it. A surplus of heat can make operations less safe since hot-running gear reducers are notorious for scorching distracted workers. In terms of reliability, gearbox designers tend to lubricants of higher viscosities, which contradicts efficiency.

There exists a variety of gearing, with every type having distinct positives and negatives, so it is worth considering each. Some examples of gears used commonly today include the following: There is worm gearing, which is exorbitantly priced, especially when it comes to right-angle applications. Self-locking, this type of gearing gets rid of the need for motor brakes in specific applications. On the plus side, it is hushed in tone and basically runs with relative smoothness when going in only one direction. Worm-gear efficacy goes as high as 65% to 80%. Sliding friction usually occurs, and this contributes to prodigality in terms of energy and the creation of heat as well as an increase in tooth wear. These are all contributing factors, which diminish the life of a gearbox. When the worm gears are used in applications in which the motor reverses, backlash breeds while the teeth deteriorate eventually.

Furthermore, within worm-gear reducers, so much heat is produced that designers must address pressure equalization between the inside of a reducer and the atmosphere. Installing a breather valve, which allows air in and out of the reducer is one means of pressure equalization. However, contaminants can also be let into the reducer, as can moisture, which results in oil breakdown and faster reducer failure. Including a bladder inside the reducer, to equalize pressure, is another method of pressure equalization. This can be problematic as well because bladders are likely to rupture and lead to reducer failure.

Another type of gearing is called spur gearing. It is less challenging and costly to machine as opposed to helical gearing, but more expensive than worm gearing. Basically efficient, spur gears have teeth with rolling, instead of sliding, friction, rendering heating a non-issue. Spur gears, on the other hand, have limited tooth engagement between mating gears. This places more force on individual teeth, decreasing the torque-carrying allotment of gearboxes. The teeth begin to be worn down by these factors, in addition to deforming or deflecting the teeth, which restricts the life of the gear. High torque ripple is also created by this limitation as the teeth meet and retreat, resulting in loud gearboxes.

New innovations in gearboxes are integral to a more environmentally friendly and sustainable future. The automotive industry increased over the years from 4–5 speeds to 8–10 speeds in order to close the gap between CVTs, toroidal gears, and electric vehicles (EVs). The new generation of gearboxes make it possible to reduce CO2 emissions by up to five grams per kilometer by optimizing the roller bearings and minimizing the friction of seal lips. This new cutting-edge, green technology has been developed by Volkswagen. It is the manual gearbox, the MQ281 as it is called. This efficient gearbox was initially installed in the new Passat, with almost all other Volkswagen models to follow suit. Up until this time, manual gearboxes had receded into the background. It is now remarkably being noted that only modest alterations were necessary to boost efficiency and improve consumption, resulting in a significant effect on emissions and the environment. These often overlooked and underestimated; manual gearboxes make up a prominent allotment of the gearbox market globally owing to a high installation rate.

This new design is bolstered on a 2.5 shaft concept and touts a high gear spread capped at 7.89 and a torque spectrum of 200 to 340-newton meters. While this ensures a satisfactory driving performance, including for heavy vehicles with bulky wheels, it also enables “down speeding” which is (fuel-saving) driving in high gears with low engine speed. The main impetus for this latest gearbox is primarily to improve efficiency. In addition, a bearing concept was also adapted to the gearbox, in order to mitigate friction. This design employed friction-minimized bearings in tandem with low-contact seals. Furthermore, material use and its distribution for the gearbox casing was also ameliorated. A strength-optimized housing could also be designed with the assistance of a further virtual development tool. The new encasement upholds the noise requirements of today, such as avoidance of unwanted secondary sounds. It, thus, promises increased driving comfort by facilitating less audible and discernable vibrations in the vehicle.

Even with this advancement from Volkswagen, it still should be noted that manual (standard) transmission vehicles only make up around 3% of all vehicles sold in the US. They even have a loyal group of customers that can benefit from the usually smaller production costs as compared to automatics. However, manufacturers are even starting to phase them out. A significant reason for this is to cut out manufacturing costs in general by getting rid of a possible design choice. Also, standard transmissions used to be more attractive due to fuel efficiency, but after recent advancements in automatics, this fact is no longer always the case.

There have been shifts by automakers to go for automatic transmissions to have a higher number of gears, sometimes even going between 8 and 10 speeds. These higher numbers of gears allow for more smooth acceleration and can also improve efficiency. Mercedes Benz took these advancements seriously when they announced their 9G-TRONIC 9-speed automatic transmission in 2013. This transmission has a gear ratio spread of 9.15, which helps to reduce the engine speed and helped lead to an average fuel economy of 44 mpg. Also, the transmission offers up to 1,000 newton meters of transfer torque. They say that the 9G takes up the same volume of space as the 7-speed that came before, but the 9G is lighter than this previous transmission. In addition to Mercedes, Ford and General Motors paired up to create a 10-speed automatic transmission, and Ford alone made an 8-speed automatic, both of which will aim to increase efficiency. It has been reported that the Ford 8-speed will allow for adaptive cruise control, adjust gear shift timings based on inclines, declines, and curves, and will also adjust clutch pressure based on factors both outside and inside the vehicle.

Many manufacturers have also opted for different transmissions entirely, such as the continuously variable transmission (CVT). CVTs are known to give the same fuel efficiency as standard high-speed automatic transmissions and adds in even more smooth gear ratio transitions. This is because instead of having fixed gears and gear ratios, the CVT goes through a continuous range of gear ratios to get to the perfect one for the exact driving condition. This offers some advantage to standard automatic transmissions because, in standard gearboxes, the best gear ratio for a specific driving condition may be in between two fixed gear ratios. Nissan has developed a CVT known as XTRONIC that is designed for engines of 1.5L or 2L. They claim that it has a gear reduction ratio spread of 6 and that it shifts gears 30% quicker than its predecessor.

The topic of CVTs is important when considering purely EVs. Many people have been worried about the range of EVs being too short because batteries currently do not have enough energy density and storage capacity. A group of researchers from Australia and China carried out a study in 2018 about addressing the needs of EVs by using both CVTs and multi-speed dual-clutch transmissions (J. Ruan, et al, 2018). They determined that CVTs provide much potential for use in EVs based mostly on energy usage and fuel consumption. They showed that for a certain class of EVs, one through four-speed transmissions had consumed electricity ranging from 17.8 kWh to 15.1 kWh, respectively, while the CVT consumed electricity of 13.6 kWh, all in a city/highway combined cycle. The CVT also showed the lowest required battery capacity out of all the transmissions at 34 kWh for a range of 200 km. This is all very key information due to the inevitable advent of purely electric vehicles in the worldwide automotive market.

Another arena where the next-generation gearboxes success is critical is with the future of wind power. Although, many industry insiders are pondering if the pace of development is sustainable or if experts are biting off more than they can chew when it comes to technology. Windpower Monthly, in cooperation with wind turbine experts, Moventas, hosted an extended discussion on gearbox innovation at WindEurope 2019. It was attended by participants from prestigious companies such as GE, Acciona, Siemens Gamesa, Ingeteam, ABB, Innogy and Wood Mackenzie. The various segments in the supply chain were represented during the discourse.

Increasingly, wind turbines are being designed with low-wind conditions at the fore. Because of this factor, there is an increase in AEP expectations, rotor diameters, tower height and torque requirements. The question was posed to attendees at the event by Windpower Monthly editor, Shaun Campbell, inquiring as to whether the industry is nearing logistical and transport limits in terms of the installation, movement, and maintenance of very large components.

According to the aforementioned publication, at the conference, Jaco Nies, Chief Consulting Engineer for Systems Engineering at GE said, “If we practice for long enough and close enough to the logistical limits, companies will learn how to deal with larger components.” Nies cited the Cypress platform, where they take the tip off the blade and transport separately, rendering the logistical problems, while not null and void, greatly simplified. He stated that 15 to 20 years ago, gearboxes were much thicker, and now they are smaller in diameter but a bit longer. “So yes, there are logistical constraints, but there are also developments on the way to deal with them. People are innovative, and we are constantly redefining these limitations,” he concluded.

Moventas has a history which enabled them to meet market requirements, while countering limitations, including torque and ratio demand, which have plagued gearboxes both yesterday and today. Moventas was the premier company in the industry to provide the high torque density Exceed gearbox solution in 2014. Its technological blueprint underpins both medium and high-speed platforms, maximizes energy output, CAPEX utilization, and the introduction of the next evolution of innovation to gearbox technologies.

The main challenge for gearbox design is that wind turbine gearboxes must be able to stand up to a wide variety of shocks and loads, which would not be found in most gearbox applications. In addition to the bending forces on the shaft, which are transmitted into the gearbox, there are also abrupt changes in torque instigated by gusting and even reverse torques under severe conditions. This means that the design of the drivetrain must be able to either insulate the gearbox from these shocks, or, alternately, the gearbox must be built to tolerate them. A study from the National Renewable Energy Laboratory (NREL) for the period 2009–2016 revealed that 76% of the gear failures were related to bearings and 17% to gear teeth [www.energy.gov/eere/wind/articles/statistics-show-bearing-problems-cause-majority-wind-turbine-gearbox-failures; S. Sheng].

White etching cracks (WEC) or white etching areas (WEA), known as “early bearing failures,” affect the reliability of technical equipment, especially of wind turbines or azipods, and take many years off the lifespan of a gearbox. Premature failures and WEAs/WECs were observed in steel microstructures without any visible, metallographic default. A group of researchers from England have shown that WECs formed most frequently out of MnS inclusions, which were part of the subsurface of bearings. They attributed the crack formations to stress concentrations that appeared in certain parts of the bearings (Bruce, et al, 2015). Not much is known about the real root cause of flaking or “abnormal” flaking in the raceways originated by white etching areas/structures, but studies have shown that a variety of sources and parameters can lead to them. Researchers published a study in 2018 that focused on how lubricants, especially additives, affect the problem, and they confirmed that lubricants with metal additives usually lead to WEC formation. It was also suggested before that hydrogen originating from lubricants by arcing was a significant contribution to the formation of WECs. These researchers validated this by using TDS spectroscopy to observe oils that were heavily infused with water, which led them to conclude that water was a primary source of the hydrogen (Haque, et al, 2018). SKF tribochemistry studies (K. Stadler et al., 2013) confirmed the local generation of diffusible hydrogen under severe mixed friction contacts. Such conditions are seen in examples where a combination of lubricants and additives interact with fresh or nascent metallic surfaces.

Since many of the issues associated with gearbox wear and breakdown are related to the size of the forces with which they are inundated. One possible solution has been studied to decrease the torque by splitting the drivetrain into several smaller units, each equipped with its own gearbox and generator. Already, rotors driving eight or 16 separate gearboxes and generators have been tested to varying degrees of success. Ultimately, despite significant advances in gearbox design, the wind turbine gearbox remains a high maintenance unit. For instance, a wind turbine built with a lifespan of 20 years will likely possess a gearbox necessitating a major reworking every five-year interval.

Analogous to the human body, mechanical components such as gearboxes eventually need a check-up to ensure all is chugging along as it should be. The borescope is a highly useful tool for aiding mechanics to peer inside of complex mechanisms involved in all types of machines, such as automobiles and airplanes.

Recently, scientists have looked to more advancement regarding condition monitoring inside the wind turbine gearbox. By using new methods of process observation and control of the gears and bearings, damage can be anticipated, and this can reduce costs from unforeseen failures in the gearbox. There is a method known as an envelope spectrum that can be used as a diagnostic tool by monitoring harmonic frequencies of bearings. A group of researchers reported an improved envelope spectrum by integrating a cyclic spectral coherence along selected filtering bands. They report that this tool has been able to detect most failures under different load conditions, and the claim was verified by the National Renewable Energy Laboratory (NREL). They also saw that situations with a more significant load gave more detectability to damage, possibly due to the torque (Mauricio, et al, 2020).

The characteristics and compositions of lubricants used in wind turbines can play a significant role in the future for gearboxes. Aside from polyalphyolefins (PAO), esters and polylkyleneglycols (PAG) also entered this market. Researchers in Spain have done more studies into lubricants for wind turbine gearboxes. They investigated two ionic liquid additives into synthetic wind turbine gearbox oils for their potential in general friction and wear reductions. The two ionic liquids used were choline bis(trifluoromethylsulfonyl)imide ([choline][NTf2]) and 1-Butyl-1-methylpyrrolidinium bis(trifluoromethylsulfonyl)imide ([BMP][NTf2]). They did not prove to be very effective at reducing friction, but the wear was reduced in all the different testing conditions, with the BMP-NTf2 solution showing larger improvements as compared to the choline-based formulation (Monge, et al, 2015). Ionic liquids can be applied in all types of base oils, but their corrosivenes must be checked.

Arguably, gears are the single most fundamental invention integral to the foundation of civilization, next to the wheel, of which they are a logical extension. What is not debatable is that a typical day in our lives is unfathomable without gears, a fact of life so accepted that the average person scarcely gives this reality a second thought. Spanning from the first prototypical gears comprised of wood and bronze and hailing from China, as far back as 800 B.C.E., up through the most complex gearboxes of today, found in everything from automobiles and airplanes to wind turbines, one fact is certain, the world as we know it would be impossible without the innovative and evolving technology of the versatile and indispensable gearbox.

For more Information

Koehler Instrument Company

rshah@koehlerinstrument.com

www.koehlerinstrument.com

References

- www.apexdyna.nl/en/gear-history/

- www.windpowermonthly.com/article/1584161/future-gearboxes-happens-next

- www.moventas.com/about-moventas/

- www.motioncontroltips.com/what-is-a-gearbox/

- www.amarillogearservice.com/6-types-industrial-gearboxes-typical-uses/

- www.sciencedirect.com/topics/engineering/gearbox

- www.volkswagen-newsroom.com/en/stories/powering-into-the-future-with-a-single-gear-5819

- www.machinedesign.com/motors-drives/article/21829943/getting-the-most-out-of-gearboxes

- www.howacarworks.com/basics/how-manual-gearboxes-work

- www.powertransmission.com/blog/evolution-of-cooling-tower-gearboxes/

- quantumworks.com/multi-speed-gearboxes-can-offer-many-benefits-for-ev-powertrains-depending-on-application/

- spiborescopes.com/gearboxes/

- www.volkswagenag.com/en/news/2019/07/MQ281.html

- www.littlegatepublishing.com/2017/04/is-the-uk-seeing-the-end-of-manual-gearboxes/

- www.pkservis.com/data/web/upload/nsk/gearbox.pdf

- www.mromagazine.com/features/three-causes-of-gearbox-failure/

- peaxy.net/updates/how-does-a-gearbox-fail

- multimedia.3m.com/mws/media/530429O/cuno-auto-kleantm-filter-in-lube-oil-filtration.pdf

- www.retroarms.com/news/the-difference-between-bushings-and-bearings

- www.engineering.com/AdvancedManufacturing/ArticleID/19637/The-Past-Present-and-Future-of-Automotive-Transmission-Manufacturing.aspx

- www.greencarcongress.com/2014/03/20140306-9gtronic.html

- www.greencarcongress.com/2018/09/20180917-ford.html

- www.autoinfluence.com/11-things-you-need-to-know-about-ford-gms-10-speed-transmission/

- https://www.nissan-global.com/EN/TECHNOLOGY/OVERVIEW/cvt.html

- www.energy.gov/eere/wind/articles/statistics-show-bearing-problems-cause-majority-wind-turbine-gearbox-failures

- S. Sheng, Wind Turbine Gearbox Reliability Database, Operation and Maintenance Research Update, National Renewable Energy Laboratory, 2017, NREL/PR-5000-68347, www.nrel.gov/docs/fy17osti/68347.pdf16,17.

- Mauricio, et al. “Condition Monitoring of Wind Turbine Planetary Gearboxes Under Different Operating Conditions.” Journal of Engineering for Gas Turbines and Power, 2020, vol. 142.

- T. Bruce, et al. “Characterisation of white etching crack damage in wind turbine gearbox bearings.” Wear, 2015, vol. 338–339, 164–177.

- T. Haque, et al. “Lubricant Effects on White Etching Cracking Failures in Thrust Bearing Rig Tests.” Tribology Transactions, 2018, 61:6, 979–990.

- R. Monge, et al. “Ionic liquids as an additive in fully formulated wind turbine gearbox oils.” Wear, 2015, 328–329, 50–63.

- K. Stadler and A. Stubenrauch

- Lagerfrühausfälle in Industriegetriebeölen (Premature bearing failures in industrial gearboxes).

- Proc. Antriebstechnisches Kolloquium ATK 2013, p. 113–133, ISBN 978-3-86359-076-5.