Dana Launches Reman Program Boosting Sustainability and Extending Life Cycles for Off-Highway Drive Technologies

At MINExpo, Dana Incorporated debuted a new certified remanufacturing program for Dana Spicer Off-Highway drivetrain components that extends equipment life cycles, supports sustainability initiatives, and improves return on investment.

Currently available at Dana facilities across Europe, the Dana Certified Reman program will extend to an additional 50 locations in North America, Europe, the Middle East, Africa, and China by the end of 2025.

"The Dana Certified Reman program is all about improving machine efficiencies, supporting budget-conscious equipment owners, and contributing to the circular economy," said Roberto Marino, aftermarket commercial director for Global Off-Highway and Dana Europe Sales for Dana Incorporated. "Our approach includes reclaiming, restoring, and using genuine Spicer parts. Ultimately, we're delivering like-new performance with shorter delivery times and at a more competitive price."

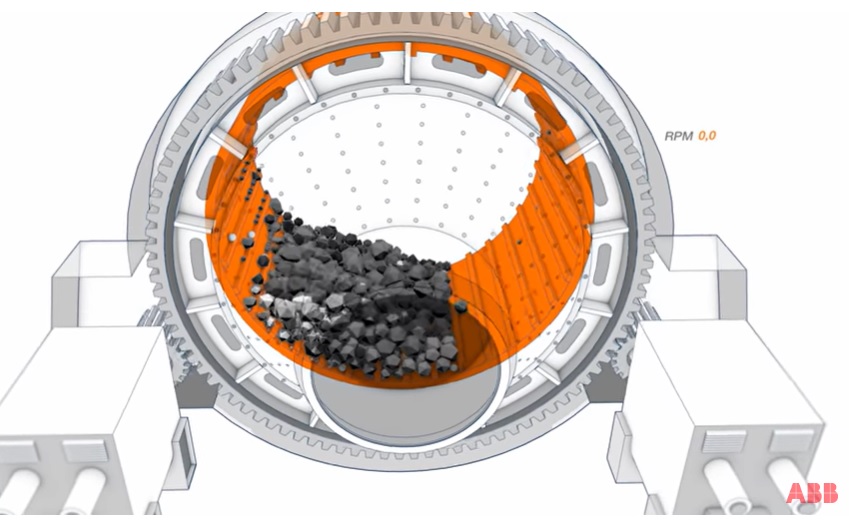

The Dana Certified Reman program restores Dana Spicer axles, transmissions, torque converters, and gearboxes to the same performance as new units from the factory.

The program goes beyond typical equipment remanufacturing services by requiring approved facilities to demonstrate investments in test benches and other specialized equipment, advanced technician training and expertise on drive technologies, strict quality protocols, and demonstrated warranty support.

In addition to improving efficiency and reducing the total cost of ownership, remanufactured drivetrains support sustainability initiatives by decreasing the flow of waste to landfills while minimizing the raw materials, energy, and water otherwise required to produce new parts.

"Dana has a hard-earned reputation for delivering superior quality and performance, which is why our process for evaluating and approving Dana Certified Reman providers is especially rigorous and detail-oriented," said Bill Nunnery, senior director of Global Aftermarket Sales and Marketing for Dana Incorporated.

Service centers approved for participation in the Dana Certified Reman program have been evaluated on more than 20 different criteria to confirm their operations meet Dana's highest standards for performance, value, ethics, sustainability, and social responsibility.

During remanufacturing, technicians follow a precise, multi-stage process including initial assessment, disassembly, reconditioning, component replacements and updates, reassembly, testing, painting, and final inspection.

Once certified, remanufactured components are backed by a warranty, and customers will receive a Dana-issued Certificate of Conformity.

Dana is sharing details of the program this week in Booth #12359 of the West Hall at MINExpo in Las Vegas. For more information and a list of approved service centers participating in the Dana Certified Reman program, visit SpicerParts.com/certified-reman.