Load

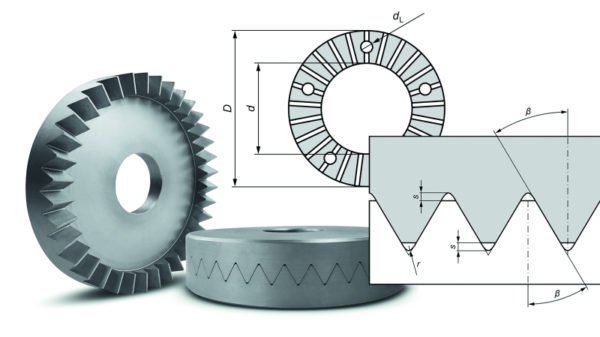

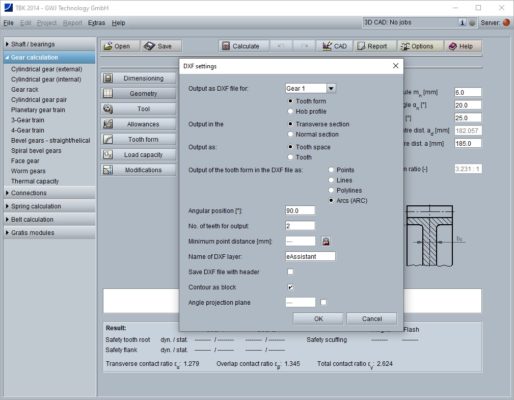

FVA Presents Transmission Design Considerations

Realistic Load Spectra Conditions are Essential for Optimal Gear Design

Read More

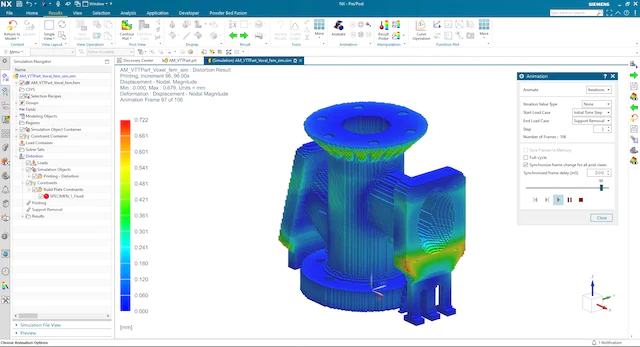

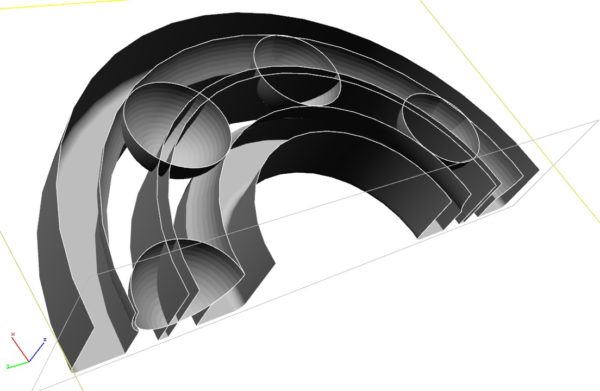

Reliable, User-Friendly Planetary Gear Unit Design

Stober Relies on FVA Workbench for Drive Verification

Read More