Manufacturing

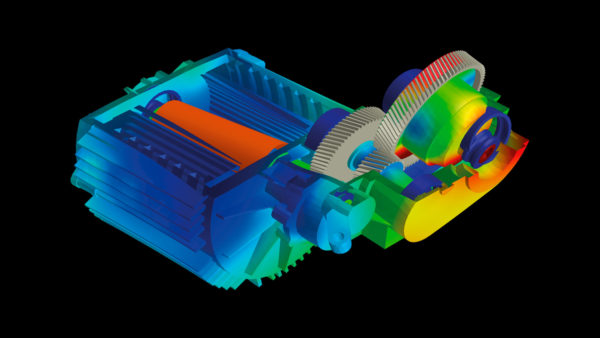

Flexibility in Gear Design

Load collectives in the FVA-Workbench expand design capabilities.

Easy Integration

Mayr components offer flexibility and guidance in robotic and automation applications

Read More

Master Power Transmission’s Automation Transformation with Ready Robotics

A leadership perspective on advanced automation integration

Read More

The Flexible Factory

See the shift in production lines and technology during Automate 2024

Read More

.jpg?height=400&t=1712314125&width=600)